Products >> Titanium >> Titanium pipe fittings

titanium fittings corrosion resistance

- Product No.:Corrosion-free butt welding titanium fittings

- Price:perform the lastest price

- Material Grade:Ti. Gr1, Gr2, Gr5, Gr7, Gr12

- Size:1/2"-36" Schedule 10S, Schedule 40S

- Test:Mechanical and chemical test

Corrosion-free butt welding titanium fittings

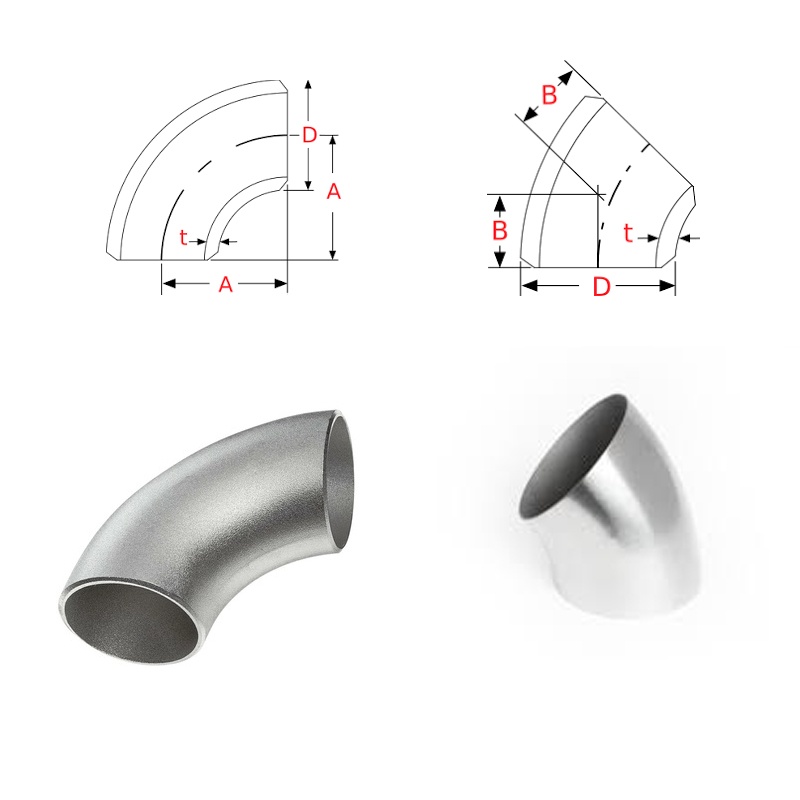

Titanium Butt-welded Elbow

Type: Titanium Elbow 45 Degrees, Titanium Elbow 90 Degrees, Titanium Elbow 180 Degrees. straight tees, reducing tees, reducers, lap-joint stub ends

Size: NPS: 1/2~48 inches

WT: SCH5S~SCH160

Standard: ANSI B16.9, ASTM B363

Material: Titanium Gr1 (3.7025), Gr2 (3.7035), Gr7 (3.7235), Gr12 (3.7105), Nickel UNS N02200 (2.4066), Zirconium 702, 704

Test: PT, RT, PMI

Certificate: EN 10204-3.1

Applications: petrochemical, chemical, vessels, machinery etc

MOQ: 1 piece

Price: Perform the latest price

Package: Plywood case

Delivery Term: 10 to 20 days

Port: Shanghai/tianjin.

|

ASTM Grade |

Alloy |

DIN |

UNS |

|

Grade 1 |

Commercially pure |

3.7025 |

R50250 |

|

Grade 2 |

Commercially pure |

3.7035 |

R50400 |

|

Grade 3 |

Commercially pure |

3.7055 |

R50550 |

|

Grade 4 |

Commercially pure |

3.7065 |

R50700 |

|

Grade 5 |

Ti-6Al-4V |

3.7164/5 |

R56400 |

|

Grade 7 |

Ti-0.15Pd |

3.7235 |

R52400 |

|

Grade 9 |

Ti-3Al-2.5V |

3.7195 |

R56320 |

|

Grade 12 |

Ti-0.3Mo-0.8Ni |

3.7105 |

R53400 |

|

Grade 23 |

Ti-6Al-4V ELI |

|

R56407 |

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China