Products >> Titanium >> Titanium pipe fittings

Titanium Gr2 Concentric Reducers

- Product No.:202382311833

- Price:10$-1200$

- Material Grade:Titanium Gr2

- Size:3/4

- Test:RT

Exploring the Benefits of Titanium Gr2 Concentric Reducers

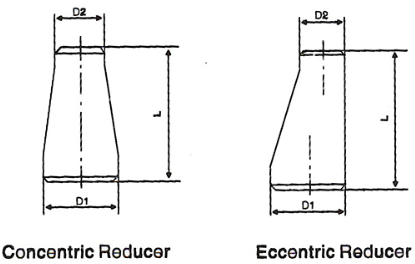

A Gr2 Titanium concentric reducer is a component in a piping system that changes the pipe size from a larger to a smaller bore. A reducer allows for a change in pipe size to meet flow requirements or to adapt to existing piping. The length of the reduction is usually equal to the average of the larger and smaller pipe diameters.

Titanium Concentric Reducers Dimension in accordance with ANSI B16.9/ASME B16.9

| Dimensions of Concentric & Eccentric Reducers ASME/ANSI B16.9 | |||||

| Nominal Pipe Size NPS | Outside Diameter at Bevel | End to end | Nominal Pipe Size NPS | Outside Diameter at Bevel | End to end |

| DlxD2 (mm) | L (mm) | DlxD2 (mm) | L (mm) | ||

| 3/4X1/2 | 26.7x21.3 | 38.1 | 4x2-l/2 | 114.3x73.0 | 101.6 |

| 3/4x3/8 | 26.7x17.1 | 4x2 | 114.3x60.3 | ||

| 4X1-1/2 | 114.3x48.3 | ||||

| 1x3/4 lxl/2 | 33.4x26.7 | 50.8 | 5x4 | 114.3x114.3 | 127 |

| 33.4x21.3 | 5x3-l/2 | 114.3x101.6 | |||

| 5x3 | 114.3x88.9 | ||||

| 5x2-l/2 | 114.3x73.0 | ||||

| 5x2 | 114.3x60.3 | ||||

| 1-1/4X1 | 42.2x33.4 | 50.8 | 6x5 | 168.3x141.3 | 139.7 |

| l-l/4x3/4 | 42.2x26.7 | 6x4 | 168.3x114.3 | ||

| 1-1/4X1/2 | 42.2x21.3 | 6x3-l/2 | 168.3x101.6 | ||

| 6x3 | 168.3x88.9 | ||||

| 6x2-l/2 | 168.3x73.0 | ||||

| 1-1/2X1-1/4 | 48.3x42.2 | 63.5 | 8x6 | 219.1x168.3 | 152.4 |

| 1-1/2X1 | 48.3x33.4 | 8x5 | 219.1x1413 | ||

| 1-1/2X3/4 | 48.3x26.7 | 8x4 | 219.1x114.3 | ||

| 1-1/2X1/2 | 48.3x21.3 | 8x3-l/2 | 219.1x101.6 | ||

| 2X1-1/2 | 60.3x48.3 | 76.2 | 10x8 | 273.1x219.1 | 177.8 |

| 2-1/2X1-1/4 | 60.3x42.2 | 10x6 | 273.1x168.3 | ||

| 2x1 | 60.3x33.4 | 10x5 | 273.1x141.3 | ||

| 2x3/4 | 60.3x26.7 | 10x4 12x10 | 273.1x114.3 | ||

| 2-l/2x2 | 70.3x60.3 | 88.9 | 12x10 | 323.9x273.1 | 203.2 |

| 2-1/2X1-1/2 | 70.3x483 | 12x8 | 323.9x219.1 | ||

| 2-1/2X1-1/4 | 70.3x42.2 | 12x6 | 323.9x1683 | ||

| 2-1/2X1 | 70.3x33.4 | 12x5 | 323.9x141.3 | ||

| 3x2-l/2 | 88.9x73.0 | 88.9 | 14x12 | 355.6x323.9 | 330.2 |

| 3x2 | 88.9x60.3 | 14x10 | 355.6x273.1 | ||

| 3X1-1/2 | 88.9x48.3 | 14x8 | 355.6x219.1 | ||

| 3X1-1/4 | 88.9x42.2 | 14x6 | 355.6x168.3 | ||

| 3-l/2x3 | 101.6x88.9 | 101.6 | 16x14 | 406.4x355.6 | 355.6 |

| 3-l/2x2-l/2 | 101.6x73.0 | ||||

| 3-l/2x2 | 101.6x60.3 | ||||

| 3-1/2X1-1/2 | 101.6x48.3 | ||||

| 3-1/2X1-1/4 | 101.6x42.2 | ||||

| 4x3-l/2 | 114.3x101.6 | 101.6 | |||

| 4x3 | 114.3x88.9 | ||||

The General size for titanium concentric reducers are from 3/4" to 48", we can produce titanium concentric reducers with seamless or welded type, and our welded titanium concentric reducers are 100% radiographic tested in accordance with ASME V and ASME VIII.

Titanium concentric reducers are widely used in various industries for their unique properties and benefits. In this article, we will explore the advantages of using titanium concentric reducers and how they can enhance the efficiency and performance of different systems.

Lightweight and High Strength

- Titanium concentric reducers are known for their exceptional strength-to-weight ratio.

- They are significantly lighter than reducers made from other materials such as stainless steel or carbon steel.

- This lightweight property makes them ideal for applications where weight reduction is crucial, such as aerospace and automotive industries.

Corrosion Resistance

- Titanium concentric reducers exhibit excellent corrosion resistance, even in harsh environments.

- They are highly resistant to corrosion caused by chemicals, acids, and saltwater.

- This corrosion resistance makes them suitable for applications in chemical processing plants, offshore oil rigs, and marine industries.

High Temperature Resistance

- Titanium concentric reducers can withstand high temperatures without losing their structural integrity.

- They have a melting point of around 1668°C (3034°F), which is much higher than other metals.

- This high temperature resistance makes them suitable for applications in heat exchangers, power plants, and other high-temperature environments.

Low Thermal Expansion

- Titanium concentric reducers have a low coefficient of thermal expansion.

- This means that they expand and contract less with temperature changes compared to other materials.

- This property makes them ideal for applications where dimensional stability is crucial, such as in precision instruments and machinery.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China