Products >> Titanium >>

Titanium pipe fittings grade 2

- Product No.:Titanium Fittings

Titanium Pipe Fittings Grade 2 Ranges:

1. Titanium Pipe Elbows: Our grade 2 titanium pipe elbows are designed to provide smooth directional changes in piping systems. They are available in various angles and sizes to suit different applications.

2. Titanium Pipe Tees: Our titanium pipe tees are used to create branching connections in piping systems. They offer excellent strength and corrosion resistance, making them ideal for demanding environments.

3. Titanium Pipe Reducers: Our grade 2 titanium pipe reducers are used to connect pipes with different diameters, ensuring efficient flow and compatibility. They are available in both concentric and eccentric designs.

4. Titanium Pipe Caps: Our titanium pipe caps are used to seal the ends of pipes, providing protection against dirt, debris, and moisture. They are available in various sizes and can be easily installed or removed.

5. Titanium Pipe Flanges: Our grade 2 titanium pipe flanges are used for the connection of pipes, valves, and other components. They are designed to withstand high pressure and temperature conditions, ensuring reliable and leak-free performance.

6. Titanium Pipe Nipples: Our titanium pipe nipples are used for extending or connecting pipes in various applications. They are available in different lengths and diameters to suit specific requirements.

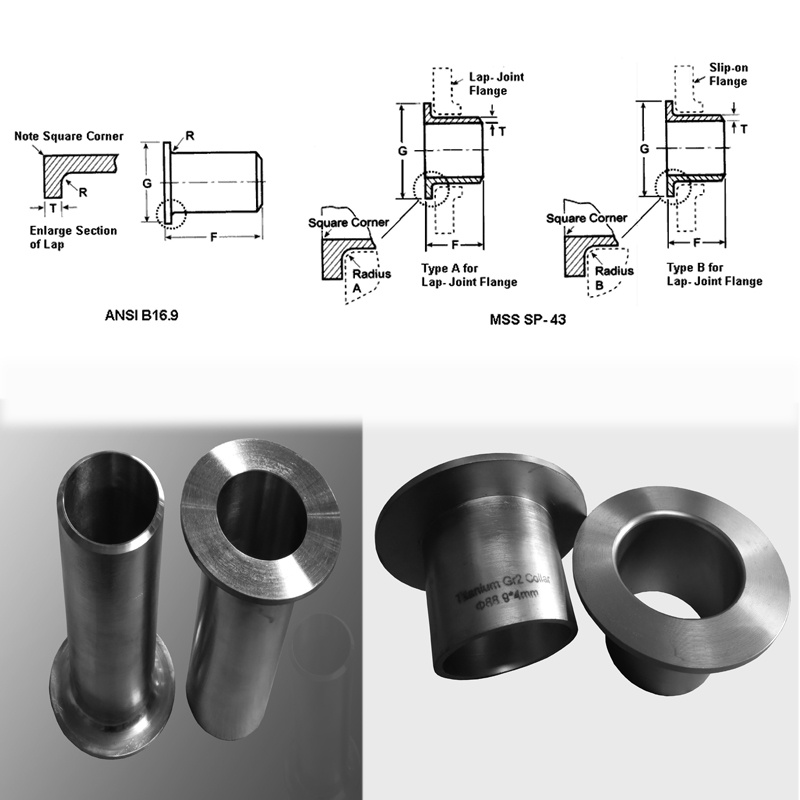

7. Titanium stub ends grade 2 are another important component in piping systems. They are used to create a secure and leak-proof connection between pipes and other fittings. Here are some key features and benefits of titanium stub ends grade 2:

7.1 Corrosion resistance: Grade 2 titanium is known for its excellent corrosion resistance, making it suitable for various harsh environments, including chemical processing, marine applications, and offshore installations.

7.2 Lightweight: Titanium is a lightweight metal, which makes it easier to handle and install. This characteristic is particularly advantageous in industries where weight reduction is a priority.

7.3 High strength: Despite its lightweight nature, grade 2 titanium exhibits impressive strength properties. This ensures the durability and longevity of the stub ends, even in demanding conditions.

7.4 Temperature resistance: Titanium grade 2 can withstand high temperatures, making it suitable for applications where elevated temperatures are involved.

7.5 Compatibility: Titanium stub ends grade 2 are compatible with a wide range of piping materials, including titanium, stainless steel, and other alloys. This versatility allows for seamless integration into various piping systems.

7.6 Low maintenance: Titanium is known for its low maintenance requirements. It is resistant to scaling, fouling, and corrosion, reducing the need for frequent cleaning or maintenance.

At Hengze Industry Co., Ltd., we strive to provide a comprehensive range of titanium pipe fittings grade 2 to meet the diverse needs of our customers. Our products are manufactured with precision and undergo strict quality control measures to ensure exceptional performance and reliability. Contact us today to learn more about our titanium pipe fittings grade 2 and how they can enhance your piping systems.

Titanium pipe fittings are commonly used in water treatment applications due to their excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility. They are particularly well-suited for use in harsh environments, such as those involving seawater, wastewater, or aggressive chemicals.

Titanium pipe fittings are available in a wide variety of types and sizes, including:

- Elbows

- Tees

- Crosses

- Reducers

- Couplings

- Flanges

- Stub ends

They can be connected to other pipes and fittings using a variety of methods, including welding, threading, and mechanical flanging.

Some of the specific benefits of using titanium pipe fittings in water treatment applications include:

- Superior corrosion resistance: Titanium is highly resistant to corrosion from a wide range of chemicals, including chlorine, ozone, and salt water. This makes it ideal for use in water treatment plants, where pipes and fittings are constantly exposed to aggressive chemicals.

- High strength-to-weight ratio: Titanium is a very strong material, but it is also relatively lightweight. This makes it ideal for use in applications where weight is a concern, such as in overhead piping systems.

- Biocompatibility: Titanium is biocompatible, meaning that it is non-toxic and does not react with the human body. This makes it ideal for use in water treatment applications where the water will be used for drinking or irrigation.

Overall, titanium pipe fittings are an excellent choice for water treatment applications due to their superior corrosion resistance, high strength-to-weight ratio, and biocompatibility.

Here are some examples of how titanium pipe fittings are used in water treatment applications:

- Seawater desalination: Titanium pipe fittings are used in seawater desalination plants to transport and process seawater. Titanium is resistant to the corrosive effects of seawater, making it ideal for this application.

- Wastewater treatment: Titanium pipe fittings are also used in wastewater treatment plants to transport and process wastewater. Titanium is resistant to the corrosive effects of wastewater, as well as to the biofouling that can occur in wastewater systems.

- Drinking water treatment: Titanium pipe fittings are used in drinking water treatment plants to transport and process drinking water. Titanium is biocompatible and does not react with the water, making it ideal for this application.

Here are some specific examples of how titanium pipe fittings are used in water treatment:

- Disinfection systems: Titanium fittings are used in disinfection systems to safely deliver and mix chemicals such as chlorine and ozone.

- Filtration systems: Titanium fittings are used in filtration systems to connect and redirect pipes and tubes, and to prevent corrosion of the filtration media.

- Ion exchange systems: Titanium fittings are used in ion exchange systems to connect and redirect pipes and tubes, and to prevent corrosion of the ion exchange resin.

- Chemical dosing systems: Titanium fittings are used in chemical dosing systems to safely deliver and mix chemicals such as acids and bases.

- Wastewater treatment systems: Titanium fittings are used in wastewater treatment systems to connect and redirect pipes and tubes, and to withstand the harsh operating conditions found in these systems.

Overall, titanium pipe fittings offer a number of benefits for water treatment applications, including:

- Improved water quality: Titanium's corrosion resistance and non-toxicity help to ensure that treated water meets all quality standards.

- Reduced maintenance costs: Titanium's long service life and low maintenance requirements help to save money on water treatment system operation and upkeep.

- Increased system reliability: Titanium's strength and durability help to reduce the risk of system failures.

In addition to the above applications, titanium pipe fittings are also used in a variety of other water treatment applications, such as:

- Cooling water systems

- Fire protection systems

- Industrial water treatment systems

- Power plant water treatment systems

Titanium Pipe Fittings Grade 2 Specifications:

|

Titanium Pipe Fittings Grade 2 Specifications |

|

|

Titanium Elbows |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Tees |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Reducers |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Stub Ends |

1/2" to 24" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Caps |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

|

|

|

Titanium Elbows |

ASTM B363, ANSI B16.9, ASME B16.9 |

|

Titanium Tees |

ASTM B363, ANSI B16.9, ASME B16.9 |

|

Titanium Reducers |

ASTM B363, ANSI B16.9, ASME B16.9 |

|

Titanium Stub Ends |

ASTM B363, ANSI B16.9, ASME B16.9, MSS SP-43 |

|

Titanium Caps |

ASTM B363, ANSI B16.9, ASME B16.9 |

Titanium Pipe Fittings Grade 2 Material Properties and Chemical Composition

|

Chemical Composition ( WT %) |

||||||||

|

Requirement |

Ti |

C |

O |

N |

H |

Fe |

Residual Element |

|

|

Remainder |

≤ |

≤ |

≤ |

≤ |

≤ |

Each |

Total |

|

|

Required |

0.08 |

0.25 |

0.03 |

0.015 |

0.3 |

0.1 |

0.4 |

|

|

Actual |

Balanced |

0.012 |

0.055 |

0.008 |

0.0014 |

0.031 |

0.1 |

0.4 |

|

Tensile Test |

||||||||

|

Requirement MIN |

Heat No. |

Tensile Strength |

Yield Strength 0.2% |

Elongation |

||||

|

[MPa] |

[MPa] |

[%] |

||||||

|

345 MIN. |

275-450. |

20 MIN. |

||||||

|

Actual |

TX-01 |

385 |

320 |

34 |

||||

|

Actual |

PX-01 |

385 |

320 |

34 |

||||

Titanium Pipe Fittings Grade 2 Types:

|

Butt-welded Titanium Pipe Fittings Grade 2 |

Titanium Elbows with 90 Degree bending |

|

Titanium Elbows with 45 Degree bending |

|

|

Titanium Returns with 180 Degrees |

|

|

Titanium Elbows with Segmental |

|

|

Titanium Elbows with Long Radius |

|

|

Titanium Elbows with Short Radius |

|

|

|

|

|

Titanium Straight Tees |

|

|

Titanium Reducing Tees |

|

|

|

|

|

Titanium Concentric Reducers |

|

|

Titanium Eccentric Reducer |

|

|

|

|

|

Titanium Stub Ends with Long Pattern |

|

|

Titanium Stub Ends with Short Pattern |

|

|

|

|

|

Titanium Caps |

Frequently asked questions for titanium pipe fittings grade 2:

-

What is grade 2 titanium? Grade 2 titanium is a commercially pure titanium alloy that offers excellent corrosion resistance, high strength, and good weldability. It is commonly used in various industries, including chemical processing, oil and gas, aerospace, and marine applications.

-

What are the advantages of using grade 2 titanium pipe fittings? Grade 2 titanium pipe fittings offer several advantages, including exceptional corrosion resistance, lightweight nature, high strength-to-weight ratio, excellent heat transfer properties, and biocompatibility. These fittings are also resistant to erosion and fatigue, making them ideal for demanding environments.

-

What types of pipe fittings are available in grade 2 titanium? Grade 2 titanium pipe fittings are available in various types, including elbows, tees, reducers, couplings, flanges, and caps. These fittings are designed to connect, control, or change the direction of the flow in titanium piping systems.

-

Can grade 2 titanium pipe fittings be used in high-temperature applications? Grade 2 titanium has a melting point of around 1,650°C (3,000°F), which makes it suitable for high-temperature applications. However, it is important to consider the specific temperature and environmental conditions to ensure the fittings will perform optimally.

-

Are grade 2 titanium pipe fittings compatible with other materials? Grade 2 titanium pipe fittings are compatible with a wide range of materials, including stainless steel, carbon steel, and other titanium alloys. However, it is essential to consider factors such as galvanic corrosion and differing thermal expansion coefficients when connecting different materials.

-

How do I properly install and maintain grade 2 titanium pipe fittings? Proper installation and maintenance are crucial for the longevity and performance of titanium pipe fittings. It is recommended to follow the manufacturer's guidelines and consult with professionals for installation. Regular inspections, cleaning, and preventive maintenance can help ensure the fittings function optimally.

-

Where can I source grade 2 titanium pipe fittings? Grade 2 titanium pipe fittings can be sourced from specialized suppliers, metal distributors, or manufacturers that deal with titanium products. It is important to choose a reliable supplier with a proven track record in providing high-quality titanium fittings.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China