Products >> Titanium >>

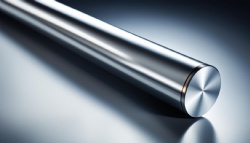

titanium alloy tube

- Product No.:2024316102721

Premium Titanium Alloy Tube Solutions | Buy Now

Welcome to our premium titanium alloy tube solutions! If you're in need of high-quality titanium alloy tubes, you've come to the right place. Our extensive range of titanium alloy tubes offers exceptional strength, corrosion resistance, and versatility for a wide range of applications. Whether you're in the aerospace, medical, or any other industry requiring reliable tubing solutions, we have the perfect titanium alloy tube for your needs.

Key Takeaways

- Titanium alloy tubes provide exceptional strength and corrosion resistance for various industries.

- These tubes are lightweight and ideal for aerospace applications, contributing to weight reduction.

- Medical-grade titanium tubes offer biocompatibility and suitability for healthcare devices and implants.

- Consider factors such as size, thickness, and specifications when selecting the right titanium alloy tube.

- Manufacturing processes ensure high-quality tubes with precise specifications.

What is Titanium Alloy Tube?

Titanium alloy tube is a specialized type of tubing that offers exceptional strength, durability, and corrosion resistance. It is composed of a combination of titanium and other metals, resulting in a material that exhibits superior properties compared to traditional tubes.

The composition of titanium alloy tube may vary depending on the specific application and desired characteristics. Common metals used in the alloy include aluminum, vanadium, and iron. The addition of these metals enhances the overall strength and performance of the tube, making it suitable for a wide range of industries and applications.

Due to its unique properties, titanium alloy tube is highly sought after in industries such as aerospace, automotive, medical, and more. Its lightweight nature, coupled with its exceptional strength, makes it an ideal choice for applications where weight reduction is crucial without compromising structural integrity.

"Titanium alloy tube is a game-changer in the world of tubing solutions, offering unmatched strength, durability, and corrosion resistance."

Whether used in aircraft manufacturing, medical implants, or high-performance sports equipment, titanium alloy tube is renowned for its ability to withstand harsh environments and demanding operating conditions. Its corrosion resistance ensures longevity and reliability, making it a cost-effective and sustainable choice.

Benefits of Titanium Alloy Tube:

- High strength-to-weight ratio

- Excellent corrosion resistance

- Superior durability and longevity

- Biocompatible and non-toxic

- Wide range of applications

From aerospace engineering to medical advancements, titanium alloy tube continues to revolutionize industries with its exceptional performance and versatility. Companies and individuals seeking reliable and high-quality tubing solutions are increasingly turning to titanium alloy tube for their critical applications.

Strength and Corrosion Resistance of Titanium Alloy Tube

Titanium alloy tubes are renowned for their exceptional strength and corrosion resistance properties, making them an ideal choice for various industries and applications. These tubes offer a unique combination of durability, lightweight construction, and resistance to environmental factors, making them highly sought after in demanding environments.

The high-strength titanium tube is designed to withstand heavy loads and extreme conditions without compromising its structural integrity. This makes it an excellent choice for industries such as aerospace, where the tube's ability to withstand high altitudes, extreme temperatures, and intense vibrations is crucial.

Furthermore, titanium alloy tubes are corrosion-resistant, ensuring longevity even in corrosive environments. This property is particularly valuable in industries like marine engineering, where exposure to saltwater can cause significant damage to conventional materials.

In addition to their strength and corrosion resistance, titanium alloy tubes also offer excellent biocompatibility, which makes them suitable for medical applications such as implants and surgical instruments. The tube's resistance to corrosion and biological degradation ensures safer and more durable medical devices.

Overall, the strength and corrosion resistance of titanium alloy tubes make them a versatile and reliable choice for various industries. Whether it's aerospace, marine engineering, or healthcare, these tubes deliver exceptional performance and durability, ensuring optimal results in demanding environments.

| Advantages of Titanium Alloy Tubes |

|---|

| High strength |

| Corrosion resistance |

| Lightweight construction |

| Biocompatibility |

Lightweight Titanium Tube for Aerospace Applications

Titanium tubes are highly sought after in the aerospace industry due to their exceptional properties, including their lightweight nature. The use of lightweight titanium tubes in aircraft design plays a crucial role in enhancing fuel efficiency, improving performance, and ensuring the overall safety of aerospace vehicles.

One of the most critical factors in the aerospace industry is weight reduction. Every pound saved in an aircraft design can significantly impact its fuel consumption and operational costs. Titanium, known for its high strength-to-weight ratio, provides an ideal solution for achieving weight reduction without compromising structural integrity.

"Titanium tubes offer aerospace engineers a lightweight alternative to conventional materials without sacrificing durability or reliability."

Advantages of Lightweight Titanium Tubes in Aerospace Applications

Titanium tubes offer several advantages that make them highly suitable for aerospace applications:

- Lightweight: With a density approximately half that of steel, titanium tubes contribute to significant weight reduction in the overall structure of an aircraft.

- High Strength: Despite its low density, titanium exhibits exceptional strength, allowing aerospace engineers to design lightweight and durable structures.

- Corrosion Resistance: Titanium's natural resistance to corrosion ensures the longevity of aerospace components, even when exposed to harsh environmental conditions.

- Heat Resistance: Titanium can withstand high temperatures, making it suitable for applications such as engine components and exhaust systems.

- Excellent Fatigue Performance: Titanium's fatigue strength and resistance to crack propagation contribute to the overall reliability and safety of aerospace structures.

The lightweight nature of titanium tubes plays a crucial role in enhancing the overall performance of aerospace vehicles. It enables increased payloads, extends the range of aircraft, and improves maneuverability. Additionally, the use of lightweight titanium tubes can reduce the environmental impact by lowering fuel consumption and greenhouse gas emissions.

"The lightweight nature of titanium tubes revolutionizes aerospace design, enabling higher performance while minimizing fuel consumption and environmental impact."

Application of Lightweight Titanium Tubes in the Aerospace Industry

The aerospace industry extensively utilizes lightweight titanium tubes for various applications, including:

| Application | Benefits |

|---|---|

| Aircraft Structures | Reduces weight, improves fuel efficiency, and enhances structural integrity. |

| Engine Components | Withstands high temperatures and speeds, contributing to increased performance and durability. |

| Exhaust Systems | Offers excellent corrosion resistance and heat dissipation properties, ensuring longevity and optimal performance. |

| Spacecraft Construction | Enables lighter spacecraft designs, facilitating efficient launch and maneuverability. |

| Aerospace Equipment | Enhances overall performance, reduces maintenance, and extends the operational life of equipment. |

The aerospace industry recognizes the unmatched benefits of lightweight titanium tubes and continues to integrate them into various aircraft and spacecraft designs. This further emphasizes the critical role of titanium in shaping the future of aerospace engineering.

Medical Grade Titanium Tube for Healthcare Applications

Titanium tubes have found extensive use in the healthcare industry due to their exceptional biocompatibility and versatility. Medical grade titanium tubes are specifically designed and manufactured to meet the rigorous standards required for applications such as implants and other healthcare devices.

One of the key advantages of medical grade titanium tubes is their ability to integrate seamlessly with the human body. The biocompatible nature of titanium minimizes the risk of rejection and promotes successful integration, making it an ideal material for medical implants. Additionally, the excellent corrosion resistance properties of titanium ensure the longevity and durability of these implants, enhancing patient safety and comfort.

Medical grade titanium tubes are utilized in a wide range of healthcare applications, including orthopedic implants, dental implants, cardiovascular stents, and surgical instruments. The lightweight yet robust nature of titanium makes it an ideal choice for these applications, as it provides structural integrity without adding unnecessary weight.

"The use of medical grade titanium tubes has revolutionized the healthcare industry, allowing for safer and more effective medical interventions. These tubes offer a balance of strength, biocompatibility, and corrosion resistance, making them an indispensable component in modern healthcare devices."

Furthermore, the versatility of medical grade titanium tubes extends beyond implants. They are also utilized in the fabrication of medical instruments and equipment, where their hypoallergenic properties and resistance to harsh chemicals are highly valued. These tubes can withstand the sterilization processes required in healthcare settings, ensuring the maintenance of strict hygiene standards.

The table below showcases some common healthcare applications that benefit from medical grade titanium tubes:

| Application | Description |

|---|---|

| Orthopedic Implants | Titanium tubes are used in the fabrication of joint replacements, bone plates, and screws to provide support and aid in the healing process. |

| Dental Implants | Titanium tubes serve as the framework for dental implants, ensuring stability, compatibility, and long-term success. |

| Cardiovascular Stents | Titanium tubes are used to manufacture stents that are inserted into blood vessels to improve blood flow and prevent blockages. |

| Surgical Instruments | Titanium tubes are utilized in the construction of surgical instruments due to their lightweight, high strength, and resistance to corrosion. |

As medical technology continues to advance, the demand for high-quality medical grade titanium tubes will only increase. The exceptional properties of titanium make it an indispensable material in the healthcare industry, enabling safer and more effective medical interventions.

Finding the Right Titanium Alloy Tube for Your Needs

When it comes to selecting the perfect titanium alloy tube for your specific requirements, there are various factors to consider. From size and thickness to specifications, choosing the right tube is crucial for optimal performance and desired outcomes.

Size Matters

The first consideration is the size of the titanium alloy tube. Depending on your project or application, you'll need to determine the appropriate diameter and length that will best suit your needs. Whether you require a small, precise tube or a larger one for heavy-duty applications, ensure that you carefully assess the sizing requirements.

Thickness and Strength

The next important factor to consider is the thickness of the titanium tube. The thickness will directly impact the strength and durability of the tube. For applications that require high strength and resistance to external pressures, opting for a thicker tube is recommended. However, if weight reduction is a priority, a thinner tube can be suitable for applications where strength is not a major concern.

Specifications and Standards

Understanding the specifications and standards of titanium alloy tubes is essential for making an informed decision. Check for industry-specific certifications and standards to ensure that the tube meets the necessary requirements. This includes factors such as chemical composition, mechanical properties, and dimensional tolerances.

"Choosing the right titanium alloy tube requires careful consideration of size, thickness, and specifications to ensure optimal performance for your specific needs."

Industry Expertise

Seeking guidance from industry experts or suppliers can prove invaluable when navigating the vast array of titanium alloy tubes available. Reach out to experienced professionals who can assist in understanding your requirements and recommend suitable options based on their expertise and knowledge of the industry.

Manufacturing Process of Titanium Alloy Tubes

When it comes to producing high-quality titanium alloy tubes, a meticulous manufacturing process is crucial. Let's explore the steps involved in crafting these exceptional tubes that meet precise specifications.

Step 1: Material Selection

The process begins with selecting the appropriate titanium alloy material. Different alloys offer varying properties and performance characteristics, ensuring the desired strength, corrosion resistance, and other essential attributes in the final product.

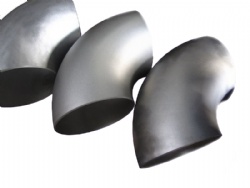

Step 2: Tube Formation

The next step involves shaping the selected titanium alloy into tubes. This can be achieved through various methods, including extrusion, where the material is forced through a die to form the desired tube shape. Other techniques such as rotary swaging or pilgering may also be employed, depending on the specific requirements of the tube.

Step 3: Heat Treatment

Heat treatment plays a critical role in enhancing the mechanical properties of titanium alloy tubes. It involves subjecting the tubes to controlled heating and cooling processes, which refine the microstructure and improve strength, hardness, and other key characteristics.

Step 4: Surface Finishing

To ensure optimal performance and corrosion resistance, titanium alloy tubes undergo various surface finishing treatments. These treatments may include processes such as pickling, passivation, or polishing to remove any impurities and create a smooth, clean surface.

Step 5: Testing and Inspection

Before titanium alloy tubes are deemed fit for use, they undergo rigorous testing and inspection to ensure their compliance with industry standards and customer specifications. Non-destructive testing methods, such as ultrasonic or visual inspections, are commonly employed to detect any flaws or defects that may compromise the integrity of the tubes.

Step 6: Quality Assurance

Quality assurance measures are implemented throughout the entire manufacturing process to ensure that the titanium alloy tubes meet the highest standards of quality. This involves monitoring various parameters, conducting thorough inspections, and maintaining strict adherence to quality control protocols.

Once the titanium alloy tubes have successfully passed all quality checks, they are carefully packaged to protect them during transit. Proper packaging guarantees that the tubes arrive at their destination in pristine condition, ready to deliver exceptional performance across a wide range of applications.

The meticulous manufacturing process of titanium alloy tubes ensures their superior quality and performance. From material selection to final inspection, every step is undertaken with precision and expertise, resulting in tubes that meet the stringent demands of various industries.

Applications and Industries Benefiting from Titanium Alloy Tubes

Titanium alloy tubes have a wide range of applications across various industries, thanks to their exceptional properties and versatility. Let's explore some of the key sectors that benefit from the use of these tubes:

Aerospace Industry

Aerospace is one of the primary industries that extensively relies on titanium alloy tubes. The lightweight nature of these tubes makes them ideal for aircraft and spacecraft applications, where weight reduction is critical. Additionally, titanium's high strength and corrosion resistance properties ensure the structural integrity and longevity of aerospace components. From aircraft frames to engine components, titanium alloy tubes play a crucial role in enhancing the performance and safety of aerospace systems.

Medical and Healthcare

The medical industry also heavily relies on titanium alloy tubes, especially medical-grade titanium tubes. These tubes are biocompatible and exhibit excellent corrosion resistance, making them suitable for various medical applications. They are widely used in orthopedic implants, dental implants, surgical instruments, and other medical devices. The biocompatibility of titanium ensures compatibility with the human body, reducing the risk of rejection or adverse reactions.

Chemical Processing

In chemical processing industries, titanium alloy tubes find extensive use due to their excellent corrosion resistance. These tubes can withstand harsh chemical environments and high temperatures, making them ideal for applications such as heat exchangers, reactors, and piping systems. The durability and longevity of titanium alloy tubes ensure reliable operation and reduce maintenance costs in chemical plants.

Oil and Gas

Titanium alloy tubes are also employed in the oil and gas industry, particularly in offshore applications. The resistance of titanium to corrosive elements and seawater makes it an excellent choice for oil platforms, heat exchangers, and subsea equipment. Titanium tubes help enhance the efficiency and durability of equipment in these demanding environments.

Automotive

The automotive industry benefits from the use of titanium alloy tubes in improving performance and fuel efficiency. These lightweight tubes are utilized in exhaust systems, turbochargers, and other components where elevated temperatures and durability are paramount. The superior strength-to-weight ratio of titanium alloy tubes contributes to weight reduction in vehicles, enhancing overall performance and reducing emissions.

Sports and Recreation

In the sports and recreation sector, titanium alloy tubes are valued for their lightweight and durable properties. These tubes are used in bicycles, golf clubs, tennis rackets, and other sports equipment. The use of titanium alloy tubes helps athletes achieve higher performance levels while ensuring durability and longevity.

| Industry | Applications |

|---|---|

| Aerospace | Aircraft frames, engine components |

| Medical and Healthcare | Orthopedic implants, surgical instruments |

| Chemical Processing | Heat exchangers, reactors |

| Oil and Gas | Oil platforms, subsea equipment |

| Automotive | Exhaust systems, turbochargers |

| Sports and Recreation | Bicycles, golf clubs |

These are just a few examples of the numerous industries and applications where titanium alloy tubes are utilized. The unique combination of strength, corrosion resistance, and lightweight properties make these tubes indispensable in various sectors.

Conclusion

In conclusion, titanium alloy tubes offer unparalleled strength, corrosion resistance, and lightweight properties, making them a desirable choice in various industries. Whether for aerospace applications, healthcare devices, or other specialized fields, titanium alloy tubes deliver exceptional performance.

When selecting a titanium alloy tube, it is essential to consider factors such as size, thickness, and specifications to ensure the right fit for your needs. The manufacturing process of these tubes guarantees high quality, precise specifications, and adherence to industry standards.

With their wide range of applications and industries, titanium alloy tubes have proven their value and versatility. From aerospace to medical sectors, these tubes play a crucial role in enhancing performance, promoting innovation, and enabling technological advancements. The future of titanium alloy tubes looks promising, as they continue to revolutionize various fields with their exceptional properties.

FAQ

What is titanium alloy tube?

Titanium alloy tube is a tube made from a combination of titanium and other metallic elements. It offers superior strength, durability, and corrosion resistance compared to traditional materials.

What are the key features of titanium alloy tube?

Titanium alloy tube is known for its high-strength properties, excellent resistance to corrosion, lightweight nature, and suitability for various industries such as aerospace and medical.

What are the benefits of using titanium alloy tube in aerospace applications?

Titanium alloy tube is lightweight, making it ideal for aerospace applications where weight reduction is crucial. It also offers exceptional strength and corrosion resistance, ensuring reliable performance in challenging environments.

How is titanium alloy tube used in the medical field?

Titanium alloy tube is extensively used in the medical field due to its biocompatibility and corrosion resistance. It is commonly used for implants, surgical instruments, and medical devices where long-term durability and compatibility with the human body are essential.

How do I choose the right titanium alloy tube for my specific needs?

When selecting a titanium alloy tube, consider factors such as size, thickness, specifications, and intended application. It is recommended to consult with experts or suppliers who can provide guidance based on your specific requirements.

What is the manufacturing process of titanium alloy tubes?

The manufacturing process of titanium alloy tubes involves several steps, including melting the titanium alloy, forming the tube through extrusion or seamless rolling, and further processing to obtain the desired dimensions and properties.

In which industries are titanium alloy tubes commonly used?

Titanium alloy tubes find applications in various industries, including aerospace, medical, oil and gas, chemical processing, automotive, and sports equipment manufacturing. They are particularly beneficial in aerospace and medical sectors due to their unique properties.

Can titanium alloy tubes be purchased online?

Yes, you can conveniently purchase titanium alloy tubes online. There are reputable suppliers and distributors offering a wide range of titanium alloy tubes to meet different specifications and requirements. Make sure to choose a reliable supplier with a good reputation for product quality and customer service.

Are there different grades of titanium alloy tubes?

Yes, there are different grades of titanium alloy tubes available, each designed for specific applications and industries. Common grades include titanium Grade 5 (Ti-6Al-4V), Grade 2 (Ti-CP), and Grade 9 (Ti-3Al-2.5V). The choice of grade depends on the desired properties and the intended use of the tube.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China