Products >> Titanium >>

Titanium Fittings Supplier

- Product No.:2024324104849

ASTM B363 Titanium Fittings Supplier: Your Ultimate Guide

When it comes to high-quality titanium fittings, ASTM B363 is the gold standard. As a leading supplier, we offer a wide range of seamless and welded fittings that meet the strict requirements of this specification.

Why Choose ASTM B363 Titanium Fittings?

1. Corrosion Resistance: Titanium is known for its exceptional corrosion resistance, making it ideal for various industries, including chemical processing, marine, and aerospace.

2. Strength and Durability: Our ASTM B363 fittings are made from unalloyed titanium and titanium alloys, ensuring strength, durability, and longevity.

3. Wide Size Range: Whether you need fittings in sizes from 1/2" to 48", we’ve got you covered. Choose from schedule 5s, schedule 10s, and schedule 40s.

4. Material Grades: Our inventory includes fittings in titanium grade 1, grade 2, grade 5 (Ti-6Al-4V), grade 7, and grade 12. Each grade offers unique properties to suit your specific application.

Testing and Quality Assurance

Before our fittings reach you, they undergo rigorous testing, including:

• Positive Material Identification (PMI): Ensures material composition and quality.

• Radiographic Testing (RT): Detects internal defects.

• Ultrasonic Testing (UT): Identifies surface and subsurface flaws.

Let’s dive deeper into the various types of titanium fittings covered by ASTM B363. Whether you’re designing a complex industrial system or need fittings for a specific application, understanding these types will help you make informed decisions:

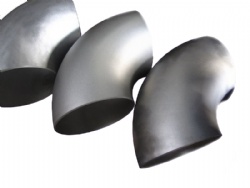

1. Elbows:

Available in 45-degree, 90-degree, and 180-degree bends.

Elbows allow changes in direction while maintaining fluid flow.

Ideal for piping systems where turns are necessary.

2. Tees:

Formed like the letter “T.”

Used to create branches in pipelines.

Commonly used for connecting three pipes at right angles.

3. Reducers:

Used to transition between pipes of different diameters.

Available in concentric and eccentric designs.

Concentric reducers maintain a straight centerline, while eccentric reducers have an offset centerline.

4. Stub Ends:

Non-standard fittings used for flange connections.

One end is flanged, while the other end is plain.

Often paired with lap joint flanges.

5. Caps:

Also known as end caps or pipe end covers.

Seal the end of a pipe or fitting.

Prevent debris, dust, or contaminants from entering the system.

6. Couplings:

Connect two pipes or tubes directly.

Available in various designs, including threaded, socket weld, and butt weld couplings.

Used for repairs, extensions, or joining pipes of the same diameter.

7. Plugs:

Close off the end of a pipe or fitting.

Similar to caps but with a male threaded connection.

Used for temporary closures or testing purposes.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China