Products >> Tungsten >>

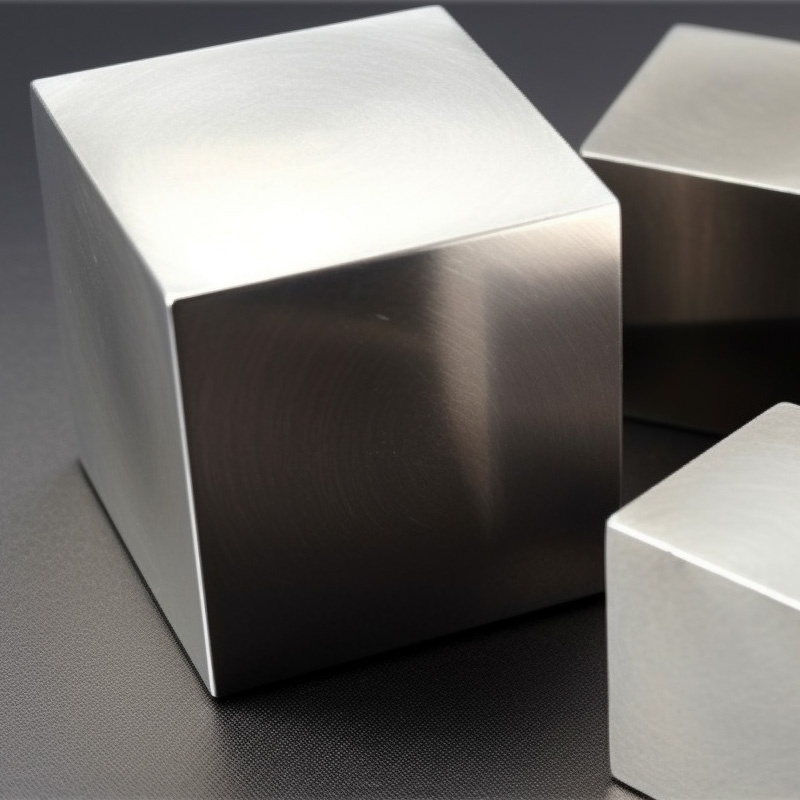

2 inch Tungsten Cube

- Product No.:Tungsten cubes

- Material Grade:99.95% Purity Tungsten

- Size:Customized

- Test:Mechanical and chemical test

Hengze Industry Co., Ltd. offer high-quality 2 inch tungsten blocks that are known for their durability, strength, and excellent thermal and electrical conductivity. Our team ensures strict quality control throughout the manufacturing process to meet international standards.

With our expertise and vast experience in the industry, we can cater to the diverse needs of different industries, including energy, electronics, and more. Our tungsten blocks are widely used for applications such as radiation shielding, heat sinks, electrical contacts, furnace parts, and various precision machining.

We take pride in our prompt delivery, competitive pricing, and exceptional customer service. Whether you have specific requirements or need assistance in selecting the right tungsten blocks for your project, our dedicated team is here to provide you with tailored solutions.

Trust Hengze Industry Co., ltd. as your reliable supplier of tungsten blocks. Contact us today to discuss your tungsten block needs and benefit from our high-quality products and reliable service.

Tungsten Cube Weight Guide - Heavy & Solid Feel

Welcome to our comprehensive guide to tungsten cube weights. If you're fascinated with unique objects that offer impressive weight and solidity, then tungsten cubes are perfect for you. In this guide, we will take a deep dive into the world of tungsten cube weights, including their density and allure. We will also explore the various types of tungsten alloys used in cube production, providing you with all the insights you need. So, are you ready to learn more about tungsten cube weights and alloys?

Key Takeaways

- Tungsten cube weights offer unique and impressive weight and solidity

- Tungsten cubes can be made from different alloys like tungsten heavy alloy

- There are many places where you can buy high-quality tungsten cubes

- Tungsten cubes offer various benefits like durability, resistance to corrosion, and aesthetic appeal

- Caring for and maintaining your tungsten cubes properly is key to their longevity

Understanding Tungsten Cube Weight

As we explored in the previous section, tungsten cubes are known for their impressive weight and density. But what exactly contributes to this weight? Tungsten, the primary material used in cube production, has a density of 19.3 g/cm³ - over 1.5 times denser than lead. This density adds substantial weight to the cubes, making them significantly heavier than other materials of the same size.

Furthermore, tungsten cubes are often made from tungsten heavy alloys. These alloys contain a high percentage of tungsten, combined with other metals such as nickel, copper, and iron. The addition of these metals enhances the weight and density of the cubes even further, resulting in a solid and substantial feel.

When buying tungsten cubes, it's essential to understand the density and weight of the cubes to ensure you get the desired level of heft. Measuring the dimensions of the cube, and calculating its volume and weight can help you determine whether it's the right fit for your collection or application.

"The weight of a tungsten cube is not just a physical attribute, but also an emotional one. Holding a tungsten cube in your hand provides a sense of stability and durability that's hard to find in other materials."

Tungsten Heavy Alloy Cube Properties

|

Tungsten Heavy Alloy |

Density (g/cm³) |

Magnetic Properties |

|

90W7Ni3Fe |

17.0 |

Magnetic |

|

91W6Ni3Fe |

17.5 |

Magnetic |

|

92.5W5Ni2.5Fe |

17.6 |

Magnetic |

|

93W4Ni3Fe |

17.9 |

Magnetic |

|

95W3Ni2Fe |

18.0 |

Non-Magnetic |

|

97W2Ni1Fe |

18.5 |

Non-Magnetic |

Tungsten heavy alloy cubes come in various grades, with different densities and magnetic properties. Pure tungsten cubes have a density of 19.3 g/cm³ and are non-magnetic. In contrast, tungsten heavy alloys can be both magnetic and non-magnetic, depending on their composition.

For example, 90W7Ni3Fe, which contains 90% tungsten, 7% nickel, and 3% iron, has a density of 17.0 g/cm³ and is magnetic. On the other hand, 97W2Ni1Fe, which contains 97% tungsten, 2% nickel, and 1% iron, has a density of 18.5 g/cm³ and is non-magnetic.

Understanding the properties of tungsten heavy alloys can help you buy the right grade for your specific needs, whether it's for radiation shielding or ballast weights for aircraft.

Where to Buy Tungsten Cubes?

Looking to purchase a high-quality tungsten cube of your own? Fortunately, there are many online sources available to buy these intriguing objects. To help you find the best deals and highest quality products, we've compiled a list of trusted sources for tungsten cube buy.

|

Retailer Name |

Website |

|

Midwest Tungsten Service |

www.midwesttungsten.com |

|

Tungsten Republic |

www.tungstenrepublic.com |

|

Tungsten Affinity |

www.tungstenaffinity.com |

|

Tungsten Cube |

www.tungstencube.com |

Be sure to check the specifications of the tungsten cube before making a purchase. Look for information on the type of tungsten alloy used, as well as the weight and dimensions of the cube. Consider the reputation and customer reviews of the retailer before making a final decision to ensure that you receive a high-quality product.

Note: This is not an exhaustive list and there are many other retailers you can explore to buy your tungsten cube. Also, it is worth noting that not all retailers provide tungsten heavy alloy cube.

The Benefits of Tungsten Cubes

While the weight of tungsten cubes is undoubtedly their most notable feature, these unique objects offer many benefits beyond their impressive heft. Here are just a few of the advantages of owning a tungsten cube:

1. Durability: Tungsten is one of the toughest materials on earth and is highly resistant to scratches and dings. As a result, tungsten cubes are incredibly durable, making them an ideal choice for long-term use.

2. Resistance to Corrosion: Unlike some metals that can rust or corrode over time, tungsten is highly resistant to corrosion. This means that tungsten cubes will retain their shiny, polished appearance for years to come.

3. Aesthetic Appeal: Tungsten cubes have a sleek, modern appearance that makes them a popular choice for collectors and enthusiasts. Whether displayed on a desk or shelf, a tungsten cube is sure to attract attention and admiration.

4. Versatility: Due to their impressive weight and durability, tungsten cubes have a wide range of applications. They can be used as paperweights, decorative objects, or even as poise weights in precision balances.

5. Variety: Tungsten cubes can be made from different alloys, each with its own unique properties. From pure tungsten to tungsten heavy alloy cubes, there are many options available to suit different needs and preferences.

To experience these benefits for yourself, consider purchasing a high-quality tungsten cube from a reputable vendor. With its impressive weight and numerous advantages, a tungsten cube is a valuable addition to any collection.

Exploring Tungsten Cube Alloys

Tungsten cubes are more than just dense objects with striking weight. They can also be made from different alloys, each with its unique properties. From pure tungsten to tungsten alloys, the specific characteristics of each alloy make them suitable for different applications. Understanding the differences can help you source the best material for your project.

Tungsten Heavy Alloy Cube

Tungsten heavy alloy cubes are a common choice due to their durability and high-density properties. They are composed of tungsten, copper, and nickel, making them resistant to corrosion and wear. These cubes are ideal for radiation shielding, as they can block gamma and x-ray radiation effectively. The high density of tungsten heavy alloy cubes makes them useful in ballast weights, kinetic energy penetrators, and fishing lures.

Pure Tungsten Cube

Pure tungsten cubes feature impressive density and a high melting point, making them suitable for high-temperature applications, such as welding electrodes and furnace elements. Their corrosion resistance makes them appropriate for use in chemical processing equipment, while their high thermal conductivity makes them useful for radiation shielding in spacecraft.

The Differences Between Tungsten Alloys

Tungsten alloys like tungsten carbide and tungsten-molybdenum are ideal for cutting tools, drilling machinery, and armor-piercing ammunition. On the other hand, tungsten-nickel-copper alloys excel in electrical and electronic applications due to their high-temperature strength and excellent thermal and electrical conductivity. To ensure the best performance and longevity of tungsten cubes, careful consideration should be given to the type of alloy used.

"Understanding the differences can help you buy the best material for your project."

The Allure of Tungsten Cube Weight

There's something undeniably captivating about the weight of a tungsten cube. Holding one in your hand is a sensory experience unlike any other. Its unexpected heaviness and solid feel provide a unique tactile feedback that entices many. The allure of tungsten cube weight is one of the primary reasons for their popularity among collectors and enthusiasts alike.

Part of the fascination with tungsten cube weight is due to the materials used to create them. Tungsten heavy alloy cubes, in particular, are prized for their significant weight-to-size ratio, with some cubes weighing up to 1 pound or more. The density and mass of tungsten make it an ideal material for creating these heavy objects, providing a satisfying heft that impresses anyone who holds them.

But the appeal of tungsten cube weight goes beyond its physical properties. These intriguing objects also offer various benefits, including their durability and resistance to corrosion. Additionally, many people appreciate the aesthetic appeal of tungsten cubes, with their smooth surfaces and polished finishes.

"There's something undeniably captivating about the weight of a tungsten cube."

Exploring Tungsten Cube Alloys

Tungsten cubes can be made from different alloys, each with its own unique properties. Pure tungsten and tungsten heavy alloy are two of the most common materials used in cube production. Pure tungsten cubes offer the highest density and are heavier than most other materials, while tungsten heavy alloy cubes are slightly less dense but still significantly weighty.

The specific alloy used to create a tungsten cube depends on the desired properties. For example, some tungsten alloys are more ductile than others, making them suitable for applications where flexibility is required. Others have higher melting points, which makes them ideal for use in high-temperature environments.

The Benefits of Tungsten Cubes

In addition to their impressive weight and solid feel, tungsten cubes offer various benefits. Their durability and resistance to corrosion make them ideal for use in harsh environments, and their high melting points allow them to withstand extreme temperatures. Tungsten cubes are also used in medical applications, such as radiography and radiation therapy due to their ability to absorb and shield against radiation.

Where to Buy Tungsten Cubes

If you're interested in purchasing your own tungsten cube, there are various trusted sources available online. However, it's essential to ensure that you're buying high-quality tungsten cubes from reputable vendors. Look for vendors that specialize in tungsten and offer a range of products, including different sizes and alloys.

The Fascinating World of 2-Inch Tungsten Cubes

If you're impressed by the weight of tungsten cubes, wait till you experience the 2-inch variety! These cubes are significantly heavier than their smaller counterparts, providing an even more satisfying and substantial feel. But what exactly makes these cubes so special? Let's take a closer look!

Firstly, 2-inch tungsten cubes are made from high-quality tungsten alloys, which contribute to their impressive weight and durability. Unlike pure tungsten, tungsten alloys are tougher and more resistant to wear and tear, making them suitable for a wide range of applications. In fact, tungsten heavy alloy cubes are widely used in industries like aerospace, defense, medical and more.

Another reason why 2-inch tungsten cubes are so fascinating is their aesthetic appeal. These cubes are beautifully crafted, with a solid and sleek design that adds to their allure. They're perfect for collectors and enthusiasts, who appreciate the unique combination of weight and beauty that these cubes offer.

“2-inch tungsten cubes are a favorite among collectors for their impressive heft and aesthetic appeal.”

So, where can you buy 2-inch tungsten cubes? There are many online stores and specialty retailers that offer these cubes at competitive prices. Make sure to do your research and opt a trusted source, so you can be sure of the quality and authenticity of your purchase.

Overall, 2-inch tungsten cubes are a remarkable example of the fascinating world of tungsten weights. Whether you're a collector, enthusiast, or simply curious about these intriguing objects, the 2-inch variety is definitely worth exploring!

Tungsten cubes are prized for their impressive weight and solid feel, making them ideal for various industrial applications. Let's examine the benefits of tungsten cubes in different fields:

Radiation Shielding

Tungsten is an effective material for radiation shielding due to its high density and excellent radiation absorption capabilities. It is often used in x-ray machines, nuclear reactors, and medical devices to protect against harmful radiation exposure. Tungsten cubes provide an ideal solution for use in radiation shielding, thanks to their heavy and dense construction, making them simple to place and move.

Aerospace Industry

The aerospace industry often uses tungsten in alloys to increase strength and sturdiness. Tungsten cubes are used in aircraft balancing, vibration damping, and as a counterweight for satellite positioning systems. Manufacturers often utilize tungsten cubes due to their high density, which allows for more compact designs and a more streamlined flight profile.

Ballast Weights

Tungsten cubes are a popular choice for use as ballast weights. These weights help to balance and stabilize boats, submarines, and other marine vehicles. Tungsten is corrosion-resistant and provides a compact and efficient solution to weight-based systems. Tungsten cubes are highly durable and able to withstand the harsh marine environment, making them ideal for long-term use in ballast systems.

"The impressive heft and density of tungsten cubes make them an ideal solution for a wide range of industrial applications."

Other applications for tungsten cubes include sports equipment, including golf club weights, and as a tool for calibrating scales and balances.

If you're looking to purchase tungsten cubes for use in your industry or personal pursuits, be sure to source them from reputable suppliers to ensure product quality.

Care and Maintenance of Tungsten Cubes

To ensure your tungsten cubes maintain their impressive weight and allure, proper care and maintenance are crucial. Here are some essential tips:

Cleaning

To clean your tungsten cube, use a soft cloth or microfiber towel and gently wipe the surface. Do not use harsh chemicals or abrasives that may scratch or damage the cube's finish.

"Regular cleaning not only maintains the appearance of the cube, but also removes any oils or contaminants that may affect its weight."

Storing

When not in use, store your tungsten cube in a dry, cool place away from direct sunlight or heat sources. Avoid exposing it to extreme temperatures or humidity that may cause the cube to corrode or tarnish.

Protecting

To protect your tungsten cube from scratches or damage, consider purchasing a protective case or display stand. This will not only keep your cube safe, but also showcase its impressive weight and visual appeal.

Tungsten Cube Maintenance Checklist

|

Action |

Frequency |

Reason |

|

Clean with soft cloth |

Weekly |

Remove oils and contaminants |

|

Store in dry, cool place |

Always |

Prevent corrosion and tarnishing |

|

Protect with case or display stand |

As needed |

Prevent scratches or damage |

By following these simple tips, you can ensure your tungsten cube remains a valuable addition to your collection.

Conclusion

In conclusion, the weight and solidity of tungsten cubes are truly remarkable. Whether you're a collector, scientist, or enthusiast, there is no denying the allure of these objects. Understanding the various tungsten alloys used in cube production, including tungsten heavy alloy cubes, can enhance your appreciation for their impressive weight.

If you're interested in owning a tungsten cube, there are numerous trusted sources where you can buy high-quality versions. Beyond their aesthetic appeal, tungsten cubes offer a range of benefits, including exceptional durability and resistance to corrosion.

Whether you're using a tungsten cube in an industrial application or simply as a paperweight on your desk, proper care and maintenance are crucial to ensuring its longevity. By following best practices for cleaning, storing, and protecting your tungsten cube, you can preserve its impressive weight and allure for years to come.

Overall, the fascinating world of tungsten cube weights is worth exploring, whether you're captivated by their sensory experience or their practical applications. Consider adding a tungsten cube to your collection to experience firsthand the heavy and solid feel of this remarkable material.

2 inch Tungsten cube chemical composition shown as following:

| Purity (%) | W | 99.95 | 99.95 |

| PPM | Fe | 50 | 50 |

| Ni | 30 | 30 | |

| Al | 20 | 20 | |

| SI | 30 | 30 | |

| Ca | 30 | 30 | |

| Mg | 20 | 20 | |

| Mo | 100 | 100 | |

| P | 10 | 10 | |

| C | 50 | 80 | |

| O | 30 | 30 | |

| N | 30 | 30 | |

| Pb | 1 | 1 | |

| Bi | 1 | 1 | |

| Sn | 3 | 3 | |

| Sb | 10 | 10 | |

| As | 20 | 20 |

General sizes for Tungsten cubes/Tungsten blocks

| 6.35*6.35*6.35mm | 10*10*10mm | 12.7*12.7*12.7mm |

| 20*20*20mm | 25.4*25.4*25.4mm | 38.1*38.1*38.1mm |

| 47*47*47mm | 51*51*51mm | 54.5*54.5*54.5mm |

| 103*103*103mm |

Tungsten cubes processing:

-

Extraction and purification: Tungsten is mainly obtained from its ore, wolframite or scheelite. The ore is crushed and processed to remove impurities, resulting in a tungsten concentrate.

-

Conversion to ammonium paratungstate (APT): The tungsten concentrate is dissolved in hot caustic soda solution and then treated with acid to form tungstic acid. Through further processing, ammonium paratungstate, a soluble tungsten compound, is obtained.

-

Reduction of APT: The APT is heated in a hydrogen atmosphere to reduce it to tungsten oxide, which is then reduced again with carbon or hydrogen to obtain tungsten powder.

-

Pressing and sintering: The tungsten powder is compacted into the desired shape using hydraulic presses. The compacted powder is then subjected to high-temperature sintering to fuse the particles together and create a solid tungsten block.

Quality control for tungsten cubes:

Dimensional Control: Tungsten cubes should be inspected for their dimensions, including length, width, and height. This ensures that they meet the required specifications and tolerances.

Surface Condition: The surface of tungsten cubes should be free from defects such as cracks, scratches, or other visible imperfections. Visual inspections and surface testing methods like dye penetrant inspection may be used to evaluate the surface quality.

Purity: Tungsten cubes are typically manufactured using high-purity tungsten material. Quality control measures include verifying the chemical composition and purity level of the tungsten cubes, usually through spectroscopic analysis or other material testing methods.

Density Verification: Tungsten cubes are known for their high density. Density testing methods, such as the Archimedes principle or X-ray densitometry, may be employed to measure the density and compare it against the specified values.

Packaging and Labeling: Quality control also encompasses proper packaging and labeling of tungsten cubes to ensure safe transportation, storage, and clear identification of product information.

Pure tungsten and tungsten alloy cubes or blocks have various applications due to their unique properties. Here are some common applications:

1. Ornament and Decoration: Tungsten cubes are often used as decorative pieces due to their high density and attractive metallic appearance. They can be displayed on desks, shelves, or used as paperweights.

2. Gift Items: Tungsten cubes make for unique and impressive gifts due to their weight relative to their small size. They can be given on birthdays, anniversaries, or special occasions to surprise and impress the recipients.

3. Balance Weights: Tungsten cubes are commonly used as balance weights in various industries. Their high density allows for precise weight adjustments in applications such as machinery, automotive components, aerospace, and sporting equipment.

4. Collection: Tungsten cubes are collected by enthusiasts who appreciate their rarity and unique properties. They can be part of a collection of rare and valuable metals.

5. Targets: Tungsten cubes and blocks are used as targets in various industries, including electronics, aerospace, and defense. Their high melting point and density make them suitable for applications requiring high-energy impacts or resistance to extreme conditions.

6. Industrial Applications: Tungsten cubes are used in various industrial processes, such as heat sinks, radiation shielding, electrical contacts, and high-temperature furnace components. Tungsten alloys, which often contain elements like nickel, copper, or iron, can provide enhanced properties for specific applications.

Features:of pure tungsten and tungsten alloy cube/block

The highest melting point of all metals , relatively stable chemical properties

Excellent resistance to electrochemical corrosion , not easily corroded by air .

High wearability ,High hardness, high density.

Good high temperature strength.

Good electron emission properties .

Mechanical properties mainly determined by the pressure processing and heat treatment process status.

Here are some frequently asked questions and answers for tungsten cubes:

Q: What are tungsten cubes?

A: Tungsten cubes are small, solid blocks made from pure tungsten metal. They are often used in various industries, including aerospace, defense, automotive, and medical, due to their high density and excellent heat and electrical conductivity.

Q: What are the dimensions of tungsten cubes?

A: Tungsten cubes are manufactured in various sizes, with popular dimensions ranging from 0.5 inches (12.7 mm) to 2 inches (50.8 mm) in length, width, and height.

Q: What are the advantages of using tungsten cubes?

A: Tungsten cubes offer several advantages, such as:

High density: Tungsten has the highest density among all naturally occurring elements, making it extremely useful in applications that require weight without taking up much space.

Heat resistance: Tungsten has a very high melting point, making it ideal for applications in high-temperature environments.

Electrical conductivity: Tungsten has excellent electrical conductivity properties, making it suitable for applications that require effective electrical transmission.

Radiation shielding: Tungsten is commonly used in nuclear medicine and radiation therapy as a shield against harmful radiation.

Durability: Tungsten cubes are highly resistant to corrosion and have a long lifespan, making them reliable for various demanding applications.

Q: Where can tungsten cubes be used?

A: Tungsten cubes find applications in multiple industries, including aerospace, defense, automotive, medical, and research fields. They are used as counterweights, vibration-damping masses, collimators, electrode materials, radiation shields, calibration standards, and more.

Q: Are tungsten cubes toxic?

A: No, tungsten cubes made from pure tungsten metal are generally considered non-toxic. However, it is important to handle any heavy metal with care and follow appropriate safety guidelines to avoid potential hazards.

Q: Where can I purchase tungsten cubes?

A: Tungsten cubes can be purchased from various suppliers or online stores that specialize in selling industrial-grade materials. It is advisable to research and choose reputable and reliable sources to ensure the quality and authenticity of the tungsten cubes.

Additional information: Tungsten is also called wolfram, which is famous for high density, high temperature, high melting point, 2 inch tungsten weight is around 2.52KG (5.56 LB)

What is the weight of a tungsten cube?

Tungsten cubes are known for their impressive weight. The weight of a tungsten cube can vary depending on its size and composition. On average, a 1-inch tungsten cube weighs around 1 pound (approximately 454 grams). Larger tungsten cubes, such as 2-inch cubes, can weigh around 4 pounds (approximately 1.81 kilograms) or more. The high density of tungsten contributes to its significant weight.

What is the difference between tungsten cube weight and density?

Tungsten cube weight refers to the actual mass of the cube, typically measured in pounds or grams. On the other hand, density describes the concentration of mass within a given volume. Tungsten has a high density, which means it has a significant amount of mass packed into a small volume. The density of tungsten is approximately 19.3 grams per cubic centimeter (g/cm³). So, while tungsten cubes are heavy due to their weight, they also have a high density.

Where can I buy tungsten cubes?

If you are looking to purchase tungsten cubes, there are several reputable sources available. You can find them online through specialized retailers that offer a variety of sizes and alloys. Additionally, some metalworking or scientific supply stores may carry tungsten cubes. It's recommended to research and compare prices, quality, and customer reviews before making a purchase to ensure you are getting a genuine, high-quality tungsten cube.

What are the benefits of owning a tungsten cube?

Tungsten cubes offer many benefits and are highly valued by collectors and enthusiasts. Firstly, they are incredibly durable and resistant to corrosion, making them long-lasting. Additionally, the weight and solid feel of tungsten cubes provide a unique tactile experience. Tungsten cubes are also aesthetically pleasing and often used as conversation starters or desk ornaments. Lastly, tungsten cubes have practical applications in industries such as radiation shielding and aerospace due to their high density and strength.

What are the different types of tungsten cube alloys?

Tungsten cubes can be made from different alloys, each with its own unique properties. Some common tungsten alloys used for cube production include tungsten carbide, tungsten nickel iron, and tungsten copper. Tungsten carbide is known for its exceptional hardness, while tungsten nickel iron alloys offer increased density and magnetic properties. Tungsten copper alloys combine the high-density properties of tungsten with excellent thermal and electrical conductivity.

Why are 2-inch tungsten cubes sought after?

2-inch tungsten cubes are larger and, therefore, heavier compared to their 1-inch counterparts. The increased size and weight of these cubes make them highly sought after by collectors and enthusiasts who appreciate the substantial feel and visual impact they provide. Additionally, their larger dimensions make them ideal for display purposes and can enhance the aesthetic appeal of any collection.

What are the practical uses of tungsten cubes?

Tungsten cubes have a wide range of practical applications across various industries. Due to their high density, tungsten cubes are commonly used in radiation shielding, particularly in medical and nuclear environments. They also find utility in aerospace applications, such as balancing aircraft control surfaces. Furthermore, tungsten cubes are utilized in vibration damping systems, military weaponry, and as precision weights in various scientific instruments.

How should I care for and maintain my tungsten cubes?

To ensure the longevity and pristine condition of your tungsten cubes, it is recommended to handle them with care. Avoid dropping them onto hard surfaces as this may cause damage. To clean tungsten cubes, use a soft cloth or mild soap and water, and gently wipe them down. Avoid exposing tungsten cubes to harsh chemicals or extreme temperatures. When storing, keep them in a dry and dust-free environment to prevent any potential scratches or oxidation.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China