Products >> Molybdenum >>

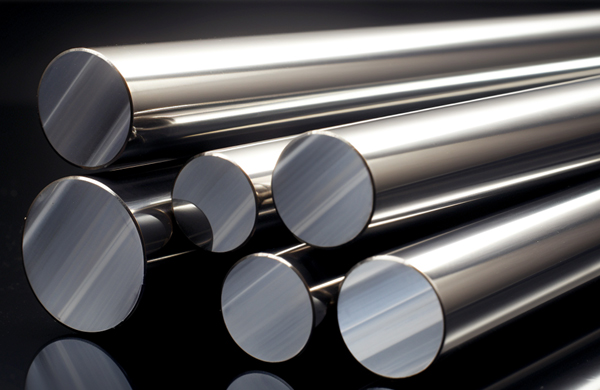

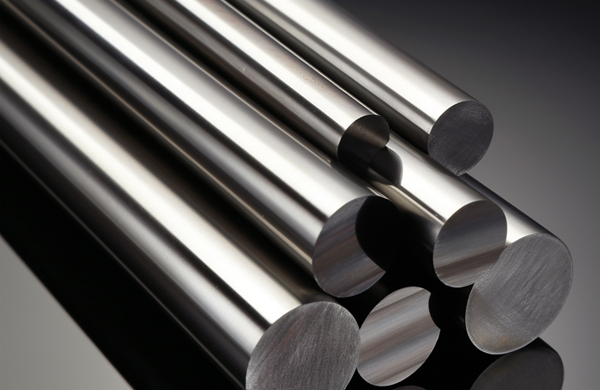

Molybdenum metal rods

- Product No.:202311251342

Molybdenum Rods: Unraveling the Versatility of a Remarkable Metal

In the realm of metallurgy, molybdenum stands out as a remarkable element, prized for its exceptional properties and diverse applications. Often overshadowed by more familiar metals like steel or aluminum, molybdenum quietly exerts its influence in various industries, shaping our world in ways we may not even realize.

Unveiling the Essence of Molybdenum

Molybdenum, represented by the symbol Mo, is a trace mineral found in the Earth's crust. It possesses a silvery-white appearance and is characterized by its high melting point, exceptional strength, and resistance to corrosion. These attributes, coupled with its ability to form alloys with other metals, make molybdenum a highly sought-after material in various fields.

Molybdenum Rods: A Pillar of Industrial Strength

Molybdenum rods, got from pure molybdenum or its alloys, serve as crucial components in a wide range of industrial applications. Their exceptional qualities make them indispensable in the following areas:

1. Steel Production: Molybdenum rods play a pivotal role in steel manufacturing, enhancing the strength, toughness, and heat resistance of steel. This fortified steel finds extensive use in construction, infrastructure, and automotive industries.

2. Chemical Catalysis: Molybdenum compounds excel as catalysts in various chemical reactions, accelerating industrial processes and improving product yields. Their catalytic prowess is particularly valuable in the production of plastics, fertilizers, and pharmaceuticals.

3. Electrical Components: Molybdenum's electrical conductivity and heat tolerance make it an ideal material for electrical components. Molybdenum rods are employed in filaments, electrodes, and heating elements, ensuring the efficient transmission and utilization of electricity.

4. Pigments and Paints: Molybdenum pigments impart vibrant and durable colors to paints and coatings. Their resistance to fading and corrosion makes them suitable for applications in harsh environments, such as automotive finishes and marine coatings.

5. Lubricants: Molybdenum-based additives enhance the lubrication properties of oils and greases, reducing friction and wear in machinery. This extends the lifespan of equipment and minimizes downtime in industrial settings.

Hengze Industry Co., Ltd.: A Trusted Supplier of Molybdenum Excellence

Hengze Industry Co., Ltd., a leading manufacturer of molybdenum products, stands as a trusted supplier of high-quality molybdenum rods. Their commitment to precision and purity ensures that their molybdenum rods meet the stringent requirements of various industries.

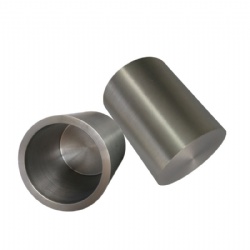

Hengze Industry's molybdenum rods are available in two primary shapes: round and square. Their round rods offer versatility and ease of machining, while their square rods provide enhanced strength and stability. Both shapes boast a purity level of 99.95%, making them among the purest molybdenum rods available.

With a keen focus on customer satisfaction, Hengze Industry provides comprehensive support and guidance to clients, assisting them in choosing the optimal molybdenum rods for their specific applications. Their commitment to quality and customer service has established them as a reputable name in the molybdenum industry.

Conclusion

Molybdenum rods, with their remarkable properties and diverse applications, serve as unsung heroes in the industrial landscape. Their ability to enhance steel, facilitate chemical reactions, power electrical components, beautify surfaces, and protect machinery makes them indispensable in shaping our modern world. As we continue to push the boundaries of technology and innovation, molybdenum rods will undoubtedly play an even more prominent role in shaping the future.

Frequently Asked Questions about Molybdenum Rods

What are molybdenum rods?

Molybdenum rods are cylindrical or square bars made of pure molybdenum or molybdenum alloys. They are characterized by their high melting point, exceptional strength, and resistance to corrosion, making them highly sought-after in various industrial applications.

What are the applications of molybdenum rods?

Molybdenum rods have a wide range of applications, including:

1 Steel production: Molybdenum rods are added to steel to enhance its strength, toughness, and heat resistance, making it suitable for construction, infrastructure, and automotive industries.

2 Chemical catalysis: Molybdenum compounds serve as catalysts in various chemical reactions, accelerating industrial processes and improving product yields, particularly in the production of plastics, fertilizers, and pharmaceuticals.

3 Electrical components: Molybdenum's electrical conductivity and heat tolerance make it an ideal material for electrical components, such as filaments, electrodes, and heating elements.

4 Pigments and paints: Molybdenum pigments impart vibrant and durable colors to paints and coatings, making them suitable for applications in harsh environments, such as automotive finishes and marine coatings.

5 Lubricants: Molybdenum based additives enhance the lubrication properties of oils and greases, reducing friction and wear in machinery, extending equipment lifespan and minimizing downtime.

What are the benefits of using molybdenum rods?

The key benefits of using molybdenum rods include:

1 High melting point: Molybdenum has a melting point of 2,617°C (4,743°F), making it one of the highest melting point metals, suitable for high temperature applications.

2 Exceptional strength: Molybdenum is highly resistant to deformation and breakage, even at high temperatures, making it ideal for structural applications.

3 Excellent corrosion resistance: Molybdenum is resistant to corrosion from various chemicals and environmental factors, ensuring long-term durability.

4 Good electrical conductivity: Molybdenum's electrical conductivity makes it suitable for electrical components, allowing efficient transmission of electricity.

What purity levels are available for molybdenum rods?

Molybdenum rods are available in various purity levels, with 99.95% being the most common and widely used. This high purity ensures the consistent properties and performance required for demanding industrial applications.

Who supplies high quality molybdenum rods?

Hengze Industry Co., Ltd. is a leading manufacturer of molybdenum products, including high quality molybdenum rods. Their commitment to precision and purity ensures that their molybdenum rods meet the stringent requirements of various industries. They offer both round and square rods in various sizes and specifications, catering to diverse application needs.

What considerations should be taken when choosing molybdenum rods?

When choosing molybdenum rods, it is crucial to consider the following factors:

1. Purity level: Choose the appropriate purity level based on the specific application requirements.

2. Shape: Choose round or square rods based on the desired strength, machining needs, and application constraints.

3. Size: Choose the appropriate diameter or square dimension to match the specific design and application requirements.

4. Supplier reputation: Opt for a reputable supplier like Hengze Industry Co., Ltd., known for consistent quality and reliable performance.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China