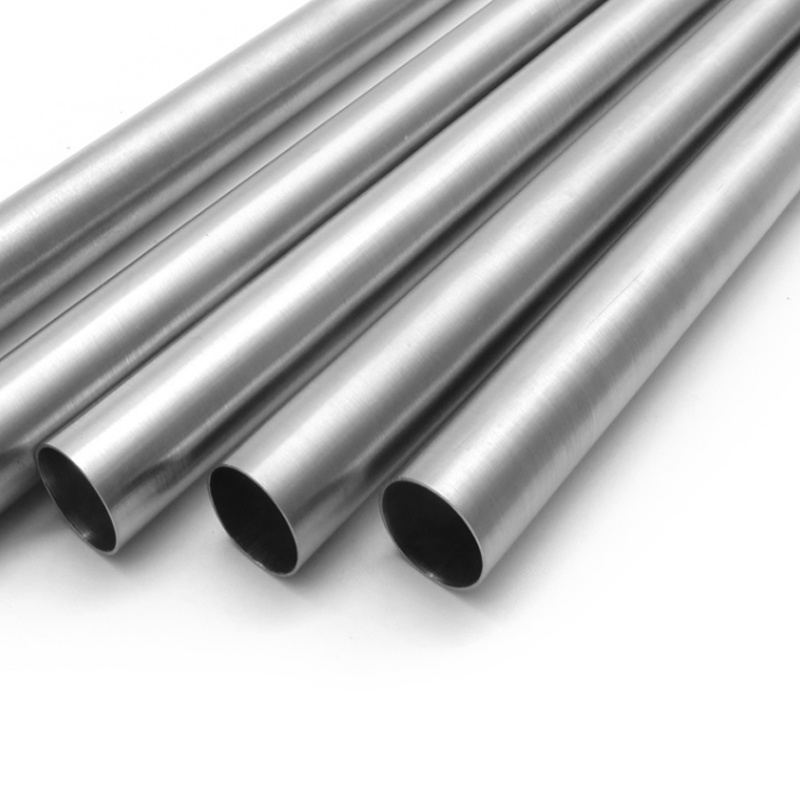

Products >> Titanium >> Titanium tube

3 inch titanium pipe for industry

- Product No.:Titanium tubes

- Material Grade:Ti. Gr1, Gr2, Gr7, Gr12

- Test:UT, hydrosatic test

Hengze Industry Co., Ltd. is a titanium tubes, titanium pipes supplier and exporter in Baoji, China.

Our titanium pipe 3 inch for industry is widely applied in etrochemical and chemical plants for corrosion resistant fluid or toxic gas.

3 inch titanium pipe for industry is manufactured with ASTM B338, ASTM B861 or ASTM B861.

3 inch titanium pipe usually comes with seamless types, on some special occasion, 3 inch titanium pipe can be supplied with welded form.

3 inch titanium pipe are cold-rolled, the surface can be grinding or pickling.

the general wall thickness for 3 inch titanium pipe is 2mm, 2.5mm, 3mm, 3.05mm, 3.5mm, 4mm, the heavy schedule for 3 inch titanium pipe can be titanium rod hollowed or forged.

3 inch titanium pipe mostly applied in chemical pipeline, environment-protection equipments and sea-water desalination.

Titanium pipes

the specification can be 1/2"-8" Schedule 5S, Schedule 10S, Schedule 40S etc

Standards can be ASTM B338, ASTM B861

Titanium tubes can be appplied for many fields such as power plants, petrochemical pipelines, heat-exchangers etc

The outer diameter can be 10mm-219mm

Our test including Eddy test, ultrasonic test, bedning, flattering test etc

Seamless titanium tubes are tubular structures made from titanium or titanium alloys that are produced without any welding seams. They are

manufactured through a process called extrusion or rotary piercing, which involves forcing a heated billet of titanium through a die to form a tube

shape.

|

Titanium tube grades |

|||

|

Grade |

UNS |

ASTM/ASME |

W.Nr. |

|

Ti Grade 1 (CP Ti) |

R50250 |

Grade 1 |

W.Nr. 3.7025 |

|

Ti Grade 2 (CP Ti) |

R50400 |

Grade 2 |

W.Nr. 3.7035 |

|

Ti Grade 3 (CP Ti) |

R50550 |

Grade 3 |

W.Nr. 3.7055 |

|

Ti Grade 7 |

R52400 |

Grade 7 |

W.Nr. 3.7235 |

|

Ti Grade 9 |

R56320 |

Grade 9 |

W.Nr. 3.7195 |

|

Ti Grade 11 |

R52250 |

Grade 11 |

W.Nr. 3.7225 |

|

Ti Grade 12 |

R53400 |

Grade 12 |

W.Nr. 3.7105 |

|

Ti Grade 16 |

R52402 |

Grade 16 |

- |

|

Ti Grade 17 |

R52252 |

Grade 17 |

- |

|

Ti Grade 26 |

R52404 |

Grade 26 |

- |

|

Ti Grade 28 |

R52254 |

Grade 28 |

- |

Exploring the Benefits of Titanium Tube

Titanium is a versatile and highly sought-after material in various industries due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. One of the most common forms of titanium used in manufacturing is titanium tube stock. In this comprehensive guide, we will explore the various aspects of titanium tube stock, including its properties, applications, manufacturing processes, and key considerations for selecting the right titanium tube stock for your specific needs.

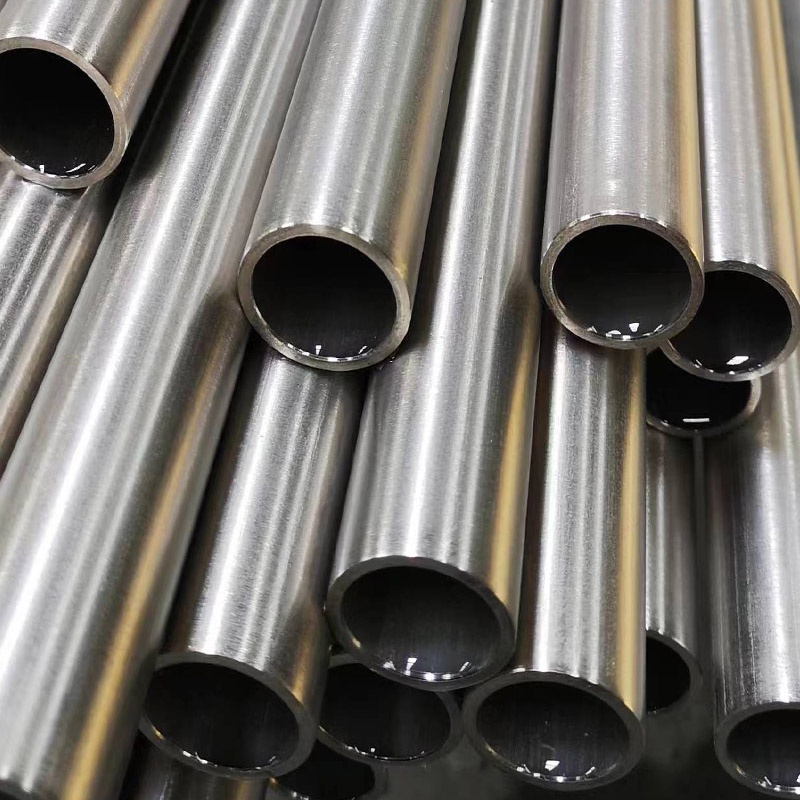

What is Titanium Tube

Titanium tube refers to a cylindrical hollow structure made from titanium. It is a type of titanium stock that is widely used in various industries for its exceptional properties. Titanium is a chemical element known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility. These properties make titanium tube stock a popular choice in industries such as aerospace, automotive, medical, and oil and gas. Titanium tubes are manufactured through a process called tube extrusion, where a solid titanium billet is heated and forced through a shaped die to form the desired tube shape.

Manufacturing process of titanium tubes

Titanium tubes can be manufactured with cold-rolled or forged or hollowed from a solid titanium rods.

Cold-rolled titanium tubes are the mostly commonly applied in industry.

Uses of Titanium Tube Stock

- Chemical processing industry

- Power plant

- Petrochemical

Advantages of Titanium Tube

- High strength-to-weight ratio

- Corrosion resistance

- Heat resistance

- Low thermal expansion

Considerations for Titanium Tube

- Cost

- Machinability

- Weldability

- Availability and sourcing

Conclusion

Titanium tube is also very cost-effective when compared to other metals, making it an ideal choice for many industrial and commercial projects. It is extremely durable and can withstand extreme temperatures and pressure. Additionally, titanium tube stock is corrosion-resistant and will not require regular maintenance. This makes it a great option for harsh environments and long-term projects. Finally, titanium tube is lightweight and easy to work with, making it a great option for projects of all sizes.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China