Products >> Titanium >> Titanium forge

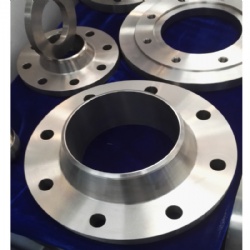

ASME B16.5 titanium lap-joint flanges

- Product No.:2023911152412

- Material Grade:Titanium alloy

- Size:1/2 inch to 48 inches

- Test:UT

Titanium lap-joint flanges are used in plumbing systems and consist of two individual parts connected together by bolts: the stub end (with its lap joint on one end) and a backing flange that bolts onto it.

Lap-joint flange connections offer easy alignment for various piping systems while offering flexible installation procedures allowing rotation or adjustment of the stub end during assembly. They are frequently employed when frequent disassembly or maintenance is necessary.

Titanium lap-joint flanges are constructed to be lightweight while boasting excellent corrosion resistance properties. Titanium is an extremely strong yet resilient metal capable of withstanding harsh chemical environments as well as temperatures reaching over 600 oF (274.4 C).

These flanges are produced according to industry standards such as ASME B16.5 or MSS-SP-44 and come in various sizes and pressure ratings to accommodate for different piping system specifications.

Titanium lap-joint flange processing and applications.

Processing Titanium Lap-Joint Flanges:

Preparation: Titanium alloy sheets or bars must first be obtained and examined to ensure quality and composition, before cutting with tools such as lasers or waterjets into desired shapes.

Machining: Once cut titanium pieces have been produced they may need additional processing such as drilling, milling or turning in order to attain the required dimensions and surface finish.

Welding: To join together the titanium components, TIG (Tungsten Inert Gas) welding or electron beam welding techniques may be employed for joining. Surface Treatments may include processes like sandblasting or polishing in order to enhance surface finish quality.

Applications of Titanium Lap-Joint Flanges:

Chemical Processing: Titanium lap-joint flanges are widely utilized within chemical processing industries due to their excellent corrosion-resistance. They're ideal for handling harsh acids and bases as well as handling potentially corrosive substances such as acids.

Oil & Gas: These flanges find uses in offshore oil & gas platforms, pipelines and refineries due to their ability to withstand harsh environments - like those present when transporting crude oil & natural gas - with great precision.

Aerospace: Titanium lap-joint flanges have long been utilized by aerospace applications due to their lightness and superior strength-to-weight ratio, making them essential in fuel systems, hydraulic systems and other vital systems.

Titanium's corrosion resistance makes it the ideal material for marine use, including shipbuilding, offshore structures and desalination plants.

Titanium Flanges in Power Generation: Titanium flanges can be found throughout a power plant's production of electricity from steam turbines, where they come into direct contact with high temperature waters or steam.

Titanium lap-joint flanges are highly esteemed for their corrosion resistance, lightweight nature, and high strength properties, making them the go-to choice in industries requiring reliable yet long-lasting plumbing systems.

Previous Product:Forged titanium alloy flanges

Next Product:Titanium welding-neck flange

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China