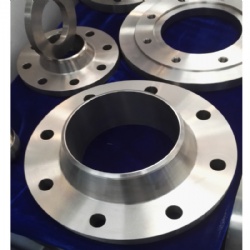

Products >> Titanium >> Titanium forge

titanium alloy flange with hot forging

- Product No.:titanium alloy flange with hot forging

- Material Grade:Titanium alloy

- Test:UT, PMI

Titanium flanges are another common pipe fitting found in piping systems, often connecting pipes, valves or other equipment together while making assembly and disassembly easier. They serve to connect these items together for seamless connection or disassembly.

Titanium flanges offer corrosion-resistance, making them suitable for industries and environments where there may be exposure to corrosive substances or environments such as chemical processing, oil and gas exploration and production, marine operations and aerospace applications. Titanium flanges are widely utilized within industries including chemical processing, oil & gas, marine and aerospace operations.

Titanium flanges come in various varieties, such as:

Weld Neck Flange: This type of flange features a long tapered hub to connect to pipes for reinforcement and leak prevention, making this ideal for applications under high pressure or temperature conditions.

Slip-On Flange: A slip-on flange fits over a pipe and is then welded securely into place, offering an efficient solution for lower pressure/temperature applications. Installing this cost-effective option requires no special tools and can easily be installed by one person.

Blind Flange: Blind flanges are used to close off the end of a pipe or provide access for inspection or maintenance purposes, with no center opening and are usually bolted in place.

Threaded Flange: Threaded flanges feature internal threads that enable them to be screwed onto pipes or fittings, typically used for smaller-sized pipes or low-pressure applications.

Socket Weld Flange: Socket weld flanges contain an inner recess designed to accommodate pipe fittings, which allows them to be inserted easily before being welded around their outer edge for a secure and leakproof connection.

Titanium flanges have found widespread applications across various industries due to their excellent corrosion resistance, strength, and other desirable qualities. Some common applications of titanium flanges include:

Chemical Processing: Titanium flanges are widely utilized in chemical processing plants that deal with aggressive chemicals or high temperature environments, including connections for pipes, valves, pumps and other equipment. They're an invaluable choice.

Titanium Flanges in Oil & Gas Industries: Titanium flanges can be found both offshore and onshore oil and gas installations, such as refineries, petrochemical plants and pipelines. Titanium flanges are widely used for connecting pipes, valves and risers in these harsh and corrosive environments.

Marine Industry: Titanium flanges find use in marine environments due to their resistance to saltwater corrosion, such as shipbuilding, offshore platforms and desalination plants. Titanium flanges provide reliable connections for pipes, fittings and equipment exposed to saltwater environments.

Titanium Flanges in Aerospace: Titanium flanges are widely utilized by aerospace industries for applications where lightweight yet strong materials are required, including aircraft engines, fuel systems and hydraulic systems.

Power Generation: Titanium flanges are widely utilized in power plants where they come into contact with high temperatures and aggressive environments, including fossil fuel and nuclear energy plants. Titanium flanges connect pipes, valves and turbines and serve to ensure efficient operations of both facilities.

Water Treatment: Titanium flanges are often utilized in water treatment plants for desalination processes, where they are exposed to high-pressure and brackish waters containing contaminants that corrode pipes and valves. As these connections provide durable corrosion-resistant connections for pipes and valves.

Titanium flange dimensions may differ depending on the standard or configuration that is being utilized, however here are some standard dimensions:

Diameter (Nominal Pipe Size, or NPS): Titanium flanges typically come in NPS sizes ranging from 1/2 inch up to 60 inches or even larger.

Flange Face Diameter (Outside Diameter or OD): The outside diameter (OD) of a titanium flange tends to be greater than its National Pipe Size, for instance a 2-inch NPS may have an OD of 6 inches or larger.

Flange Thickness: The thickness of a titanium flange depends on its pressure rating and standard, typically ranging from approximately 0.5 inch up to several inches.

Bolt Circle Diameter (BCD): The Bolt Circle Diameter (BCD) measures the diameter of a circle formed by bolt holes on a flange and may vary based on its size and standard.

Bolt Hole Diameter: Titanium flange bolt holes are typically designed to accommodate standard bolt sizes.

Previous Product:Titanium welding-neck flange

Next Product:wire electrical discharge maching cutting titanium

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China