Products >> Titanium >> Titanium forge

wire electrical discharge maching cutting titanium

- Product No.:EDM cut titanium

EDM (Electrical Discharge Machining), a method of cutting tough materials such as titanium, is highly efficient and precise.

Titanium is used in many industries including aerospace, automotive and medical because of its corrosion resistance and exceptional strength.

EDM cutting uses the principle of thermal erosion in order to remove material. An electrode,

usually made of graphite or copper, is placed between the titanium workpiece and a controlled electrical discharge.

This discharge produces intense heat which melts the titanium particles. The dielectric fluid then flushes them away.

EDM cutting titanium has the ability to cut complex shapes with high precision.

The process is not restricted by the hardness and can accurately machine titanium parts that would be difficult or even

impossible to achieve using conventional cutting methods.

EDM cutting titanium does not cause any mechanical stress to the workpiece. The process is non-contact, so there is no physical force applied to the material.

This eliminates the possibility of deformation, warping or micro-cracking, which may occur when using other cutting techniques.

EDM cutting can also produce a smooth surface finish on titanium.

By carefully controlling parameters such as voltage and current, as well the pulse duration, surface roughness can significantly be reduced.

This results in a high quality finish suitable for a variety of applications.

EDM cutting also offers excellent machining performance for titanium. Although it is a slower process than some other cutting methods.

It is reliable and can be automated to allow for mass production. This makes it an affordable option for manufacturing titanium parts,

especially when dealing complex designs and small batches.

It is important to consider certain factors when cutting titanium with EDM. Due to the high temperatures involved in the process,

it is important to take precautions to avoid potential hazards like fire or damage to workpieces.

To ensure optimal performance, it is important to maintain the dielectric fluid and electrode material.

EDM cutting is an effective method of cutting titanium because it is precise, versatile, and can achieve complex shapes.

Its non-contact nature ensures that the workpiece is not stressed, which results in an excellent surface finish and dimensional accuracy.

EDM cutting allows manufacturers to produce high-quality titanium parts with efficiency and effectiveness.

This contributes to the advancement of various industries.

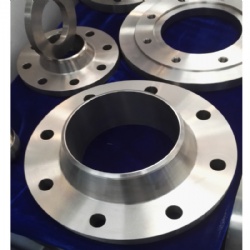

Previous Product:titanium alloy flange with hot forging

Next Product:water jet cutting for titanium alloy forgings

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China