Products >> Titanium >> Titanium forge

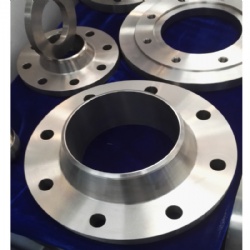

ASTM B381 Forging Titanium flanges

- Product No.:Titanium flanges

- Price:perform the lastest price

- Material Grade:Ti. Gr1, Gr2, Gr5, Gr7, Gr12

- Size:custom-made

- Test:PMI, UT

We supply a whole range of Titanium forging flanges including Titanium welding-neck flange, titanium lap-joint flange, titanium slip-on flange, titanium blind flange, titanium thread flange, titanium socket weld flange

The flanges are produced in accordance with ASTM B381, ASME B16.5 (ANSI B16.5)

Material grade: Titanium Grade 1, titanium grade 2, titanium grade 5, titanium grade 7, titanium grade 12 etc

titanium flange size: 1/2"-24"

DN15-DN1000

Pressure nominal: class 150 LB to class 2500 LB

PN 6 to PN 60

Titanium flange specifications:

The specifications of titanium flanges can vary depending on the specific requirements of the application and industry. However, here are some common specifications for titanium flanges:

The flanges are produced in accordance with ASTM B381, ASME B16.5 (ANSI B16.5)

Material grade: Titanium Grade 1, titanium grade 2, titanium grade 5, titanium grade 7, titanium grade 12 etc

titanium flange size: 1/2"-24"

DN15-DN1000

Pressure nominal: class 150 LB to class 2500 LB

PN 6 to PN 60

Titanium flanges applications:

Titanium flanges are commonly used in various industries for their excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility. Here are some applications of titanium flanges:

Oil and Gas Industry: Titanium flanges are used in offshore platforms, refineries, and pipelines due to their resistance to corrosive environments and high temperatures.

Chemical Industry: Titanium flanges are used in chemical processing equipment, such as reactors, heat exchangers, and pressure vessels, where resistance to corrosive chemicals is crucial.

Aerospace Industry: Titanium flanges are used in aircraft engines, airframes, and other components due to their lightweight nature and ability to withstand high temperatures.

Marine Industry: Titanium flanges are used in shipbuilding and offshore structures due to their resistance to seawater corrosion.

Medical Industry: Titanium flanges are used in medical implants, surgical instruments, and equipment due to their biocompatibility and resistance to bodily fluids.

Power Generation Industry: Titanium flanges are used in power plants, particularly in desalination plants, where they are resistant to the corrosive effects of saltwater.

Automotive Industry: Titanium flanges are used in high-performance vehicles, particularly in exhaust systems, due to their lightweight nature and resistance to high temperatures.

Titanium flange specifications:

The specifications of titanium flanges can vary depending on the specific requirements of the application and industry. However, here are some common specifications for titanium flanges:

Material: Titanium flanges are typically made from commercially pure titanium (grades 1 to 4) or titanium alloys (such as grades 5, 7, 9, or 12). The specific grade used will depend on the desired properties and corrosion resistance required.

Size: Titanium flanges are available in a range of sizes, typically ranging from 1/2 inch to 24 inches in diameter. Larger sizes may also be available for specific applications.

Pressure Class: Titanium flanges are designed to withstand specific pressure ratings, which are often specified using pressure class ratings such as ANSI/ASME B16.5 or DIN standards. Common pressure classes include 150, 300, 600, 900, 1500, and 2500.

Flange Type: Titanium flanges are available in various types, including weld neck flanges, slip-on flanges, blind flanges, socket weld flanges, threaded flanges, and lap joint flanges. The type of flange used will depend on the specific application and connection requirements.

Face Type: Titanium flanges can have different face types, such as raised face (RF), flat face (FF), or ring type joint (RTJ). The face type is chosen based on the sealing requirements of the application.

Standards: Titanium flanges are manufactured according to various international standards, such as ANSI/ASME, ASTM, DIN, or EN standards. These standards define the dimensions, materials, and testing requirements for the flanges.

Titanium material grades reference:

Titanium material grades reference:

| ASTM Grade | Alloy | DIN | UNS |

| Grade 1 | Commercially pure | 3.7025 | R50250 |

| Grade 2 | Commercially pure | 3.7035 | R50400 |

| Grade 3 | Commercially pure | 3.7055 | R50550 |

| Grade 4 | Commercially pure | 3.7065 | R50700 |

| Grade 5 | Ti-6Al-4V | 3.7164/5 | R56400 |

| Grade 7 | Ti-0.15Pd | 3.7235 | R52400 |

| Grade 9 | Ti-3Al-2.5V | 3.7195 | R56320 |

| Grade 12 | Ti-0.3Mo-0.8Ni | 3.7105 | R53400 |

| Grade 23 | Ti-6Al-4V ELI | R56407 |

Previous Product:water jet cutting for titanium alloy forgings

Next Product:ASTM B381 Titanium hot forgings

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China