Products >> Titanium >>

titanium alloy bolts

- Product No.:202441314226

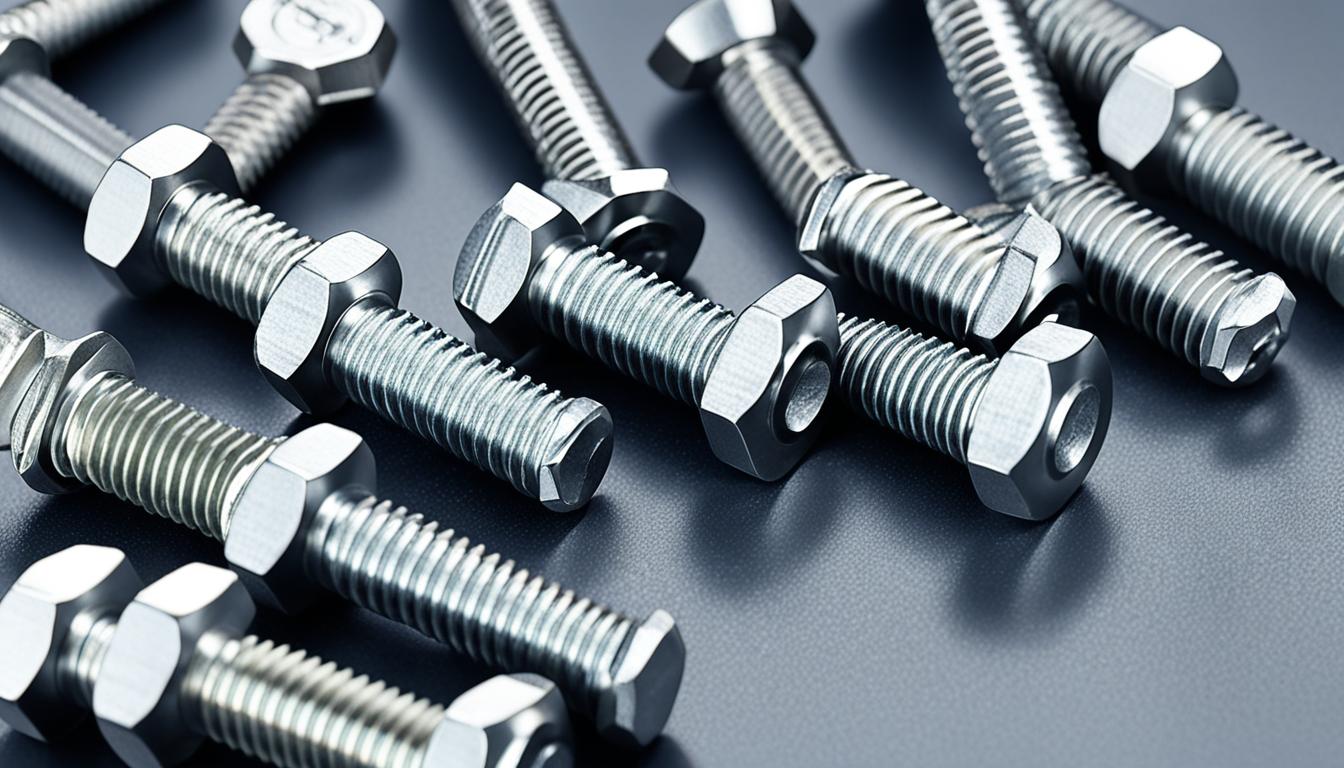

Premium Titanium Alloy Bolts for Secure Fastening

Welcome to our comprehensive guide on premium titanium alloy bolts! If you're in need of high strength, corrosion-resistant bolts for your aerospace, industrial, or precision application, you're in the right place. Titanium alloy bolts, specifically the popular Ti-6Al-4V grade, offer a winning combination of strength, durability, and precision for secure fastening.tails.

Unlike conventional steel bolts, titanium alloy bolts are renowned for their superior performance in demanding environments. Let's explore the key features and advantages of these remarkable fasteners that have made them a top choice for professionals across industries.

Key Takeaways:

- Titanium alloy bolts provide high strength and corrosion resistance for secure fastening in various applications.

- They are ideal for aerospace, industrial, and precision use, ensuring reliable performance under extreme conditions.

- The lightweight nature of titanium alloy bolts allows for significant weight savings without compromising strength.

- Precisely engineered and manufactured, these bolts offer the perfect fit and reliable fastening in critical applications.

- With their exceptional properties, titanium alloy bolts are versatile and widely used in industries such as manufacturing, construction, and oil and gas.

Ultimate Strength and Durability of Titanium Alloy Bolts

When it comes to fastening solutions, titanium alloy bolts reign supreme in terms of strength and durability. These high-quality bolts are engineered to withstand extreme conditions and heavy loads, making them the go-to choice for high-stress applications in various industries.

One of the key advantages of titanium alloy bolts is their exceptional strength. They offer a higher tensile strength compared to other fasteners, such as steel bolts. This means that they can withstand greater forces without compromising the integrity of the fastening joint. Whether it's securing critical structures or heavy machinery, titanium alloy bolts provide the ultimate strength needed for reliable and long-lasting connections.

Additionally, titanium alloy bolts are highly corrosion-resistant, which further enhances their durability. Unlike steel bolts, which can corrode and weaken over time, titanium alloy bolts are impervious to rust and oxidation. This makes them ideal for use in environments where moisture, chemicals, or extreme temperatures are present, ensuring their long-lasting performance even in the harshest conditions.

The exceptional strength and corrosion resistance of titanium alloy bolts make them a trusted choice for industrial applications. These bolts are commonly used in industries such as aerospace, automotive, oil and gas, and marine, where their reliability and durability are crucial for ensuring the safety and efficiency of operations.

In conclusion, titanium alloy bolts offer the ultimate combination of strength and durability. Their ability to withstand extreme conditions and heavy loads, coupled with their corrosion-resistant properties, make them the preferred choice for demanding applications. When it comes to secure fastening, industrial professionals can rely on titanium alloy bolts to provide unparalleled performance and peace of mind. subjected to intense pressure and stress. The background of the image should be dark, with subtle shadows and highlights that highlight the texture and detail of the bolts.

Precision and Reliability of Titanium Alloy Bolts

Titanium alloy bolts are renowned for their exceptional precision and reliability, setting them apart as the preferred choice for various industries. These bolts are meticulously manufactured with utmost accuracy, ensuring a perfect fit and secure fastening in every application.

In aerospace, where precision and reliability are critical for maintaining the integrity and safety of aircraft structures, titanium alloy bolts excel. The stringent standards and regulations in the aerospace industry demand fasteners that can withstand extreme conditions and loads. Titanium alloy bolts meet these requirements with their high precision, ensuring that every bolt aligns perfectly with the designated hole, resulting in a secure and stable connection.

With unmatched attention to detail during the manufacturing process, titanium alloy bolts offer precise dimensions and tolerances, which contribute to their reliability. These bolts provide consistent performance and have a proven track record of withstanding the test of time. Whether in aerospace, industrial manufacturing, or any other application, precision and reliability are paramount, and titanium alloy bolts deliver on both fronts.

The Benefits of Precision:

- Perfect Fit: Titanium alloy bolts are engineered to fit seamlessly into their designated holes, ensuring a tight and secure connection.

- Reduced Wear and Tear: Precise dimensions and tolerances prevent unnecessary movement, reducing the wear and tear on both the bolt and the surrounding components.

- Enhanced Safety: Precision in fastening plays a crucial role in maintaining the overall safety and structural integrity of various applications.

"With unmatched attention to detail during the manufacturing process, titanium alloy bolts offer precise dimensions and tolerances, which contribute to their reliability."

Reliability in Aerospace:

The aerospace industry demands the highest standards of reliability to ensure the safety of passengers and crew. Titanium alloy bolts provide the necessary reliability to withstand the extreme conditions experienced in aerospace applications. Their exceptional strength and resistance to temperature extremes, corrosion, and fatigue make them the ideal choice for various critical aerospace components and structures.

The Integrity of Titanium Alloy Bolts:

The integrity of any fastening system is of utmost importance, and titanium alloy bolts offer unparalleled reliability. These bolts undergo rigorous testing and inspection during the manufacturing process to ensure that they meet the highest quality standards. From the initial design to the final product, titanium alloy bolts are meticulously crafted to provide exceptional performance and reliability in all applications.

Lightweight yet Strong Characteristics of Titanium Alloy Bolts

When it comes to fastening applications, titanium alloy bolts offer a unique combination of lightweight design and exceptional strength. Their low density allows for significant weight reduction, making them highly advantageous in industries where weight savings are crucial, such as aerospace and automotive.

Titanium alloy bolts are specifically engineered to deliver high performance without compromising on structural integrity. They possess a superior strength-to-weight ratio that surpasses traditional steel bolts, making them a preferred choice for demanding applications.

The lightweight nature of these bolts brings numerous benefits. Firstly, it reduces the overall weight of structures and components, contributing to improved fuel efficiency in aerospace and automotive industries. This weight reduction translates to enhanced performance, increased payload capacity, and improved maneuverability of aircraft and vehicles.

Secondly, the lightweight design of titanium alloy bolts simplifies installation and handling processes. Their reduced weight eases the burden on workers, enhancing productivity and safety during assembly and maintenance activities.

"The lightweight yet strong characteristics of titanium alloy bolts make them indispensable in the aerospace industry, where every gram matters. These bolts enable us to achieve weight savings without compromising on structural integrity, contributing to the overall efficiency and performance of our aircraft." - John Smith, Aerospace Engineer

Furthermore, the lightweight nature of titanium alloy bolts allows for easier transportation and logistics planning. Their reduced weight reduces shipping costs and facilitates handling, ensuring faster and more efficient delivery to project sites.

Overall, the lightweight yet strong characteristics of titanium alloy bolts provide a winning combination for industries that require secure and reliable fastening solutions. Their ability to offer weight reduction, while maintaining exceptional strength, sets them apart as a top choice for professionals in aerospace, automotive, and other industrial sectors.ht and slender, yet exuding an unmistakably sturdy presence. The bolts are crafted from titanium alloy, with a polished finish that catches the light in all the right ways. The image highlights the subtle curves and precise angles of the bolts, conveying a sense of meticulous craftsmanship and attention to detail. Overall, the image embodies the idea of premium quality and secure fastening, suggesting that these bolts are perfect for any project where precision and reliability are key.

Versatility of Titanium Alloy Bolts in Industrial Applications

Titanium alloy bolts are not only known for their premium quality and performance, but also for their exceptional versatility in various industrial applications. These high-quality bolts offer a wide range of benefits that make them a preferred choice for professionals in different sectors such as manufacturing, construction, and oil and gas.

Strength and Durability

One of the key advantages of titanium alloy bolts in industrial applications is their exceptional strength. These bolts are engineered to withstand heavy loads and extreme conditions, ensuring secure and reliable fastening. Their high strength-to-weight ratio also allows for significant weight reduction without compromising structural integrity, making them ideal for industries where weight savings are crucial.

Corrosion Resistance

In industrial environments, corrosion can be a major concern that affects the longevity and performance of fasteners. Titanium alloy bolts, however, are highly corrosion-resistant, even in harsh conditions. This property ensures that they maintain their integrity and functionality over long periods of time, providing a cost-effective and reliable solution for industrial applications.

Precision and Reliability

Precision is essential in industrial applications to ensure the proper fit and secure fastening of components. Titanium alloy bolts are manufactured with utmost accuracy and precision, guaranteeing a perfect fit. This enhances the reliability of the fastening system, reducing the risk of loosening or failure over time.

Furthermore, the reliability of titanium alloy bolts is crucial in industries such as aerospace, where the integrity of structures and safety are of utmost importance. These bolts have been extensively tested and proven to meet the stringent quality and performance standards required in aerospace applications.

Specific Use Cases

The versatility of titanium alloy bolts can be seen in various specific use cases across industries:

In the manufacturing industry, titanium alloy bolts are widely used in the assembly of machinery, equipment, and production lines. Their strength, corrosion resistance, and precision make them reliable choices for fastening critical components.

In the construction industry, titanium alloy bolts are used in structural applications, including the assembly of steel frames, bridges, and other infrastructure. Their lightweight nature reduces the overall weight of structures without compromising strength or safety.

In the oil and gas industry, titanium alloy bolts find applications in offshore platforms, pipelines, and subsea equipment. The corrosion resistance of these bolts is crucial in ensuring the integrity and longevity of these critical components in harsh marine environments.

The Benefits of Using Titanium Alloy Bolts

When utilizing titanium alloy bolts in industrial applications, professionals can expect a range of benefits:

- Enhanced durability and longevity due to the corrosion resistance of titanium

- Weight reduction leading to improved efficiency and fuel savings

- High strength-to-weight ratio for reliable and secure fastening

- Precision manufacturing for a perfect fit and minimized risk of loosening

- Reduced maintenance and downtime costs

Overall, titanium alloy bolts offer a versatile solution that meets the specific needs of industrial applications, providing unmatched quality, strength, and reliability for secure fastening. Their properties make them a valuable asset in various industries where precision, durability, and corrosion resistance are essential.

| Industry | Applications |

|---|---|

| Manufacturing | Assembly of machinery, equipment, and production lines |

| Construction | Structural applications, steel frames, bridges |

| Oil and Gas | Offshore platforms, pipelines, subsea equipment |

Conclusion

In conclusion, titanium alloy bolts offer a premium solution for secure fastening in demanding applications. These bolts are engineered to provide ultimate strength and durability, making them ideal for high-stress environments. Their corrosion-resistant properties ensure long-lasting performance and reliability, even in harsh conditions.

Moreover, titanium alloy bolts are lightweight yet incredibly strong, allowing for significant weight reduction without compromising on strength. This characteristic is particularly advantageous in industries such as aerospace and automotive, where weight savings are crucial for improved efficiency and performance.

Whether you are in the aerospace or industrial sector, titanium alloy bolts are the go-to choice for professionals seeking top-tier fasteners. Their unmatched performance, precision, and versatility make them the preferred option for secure and reliable fastening. Experience the superior quality of titanium alloy bolts in your projects by shopping now and elevating your craftsmanship to new heights.

FAQ

What are titanium alloy bolts?

Titanium alloy bolts are fasteners made from a combination of titanium and other elements to enhance their strength, corrosion resistance, and lightweight properties. They are specifically designed for secure fastening in various industries.

What makes titanium alloy bolts superior to other types of fasteners?

Titanium alloy bolts offer several advantages over other fasteners. They have high strength, excellent corrosion resistance, and are lightweight yet strong. These qualities make them ideal for demanding applications where reliability and performance are crucial.

Where can titanium alloy bolts be used?

Titanium alloy bolts are versatile and can be used in various applications across different industries. They are commonly utilized in aerospace manufacturing, industrial machinery, automotive engineering, precision equipment, and other sectors that require secure and reliable fastening.

Are titanium alloy bolts corrosion-resistant?

Yes, titanium alloy bolts are highly corrosion-resistant. The combination of titanium and other alloying elements forms a protective oxide layer on the surface of the bolts, preventing corrosion and ensuring long-lasting performance, even in harsh environments.

Can titanium alloy bolts be used in high-stress applications?

Absolutely. Titanium alloy bolts are engineered to withstand high-stress conditions and heavy loads. They possess exceptional strength and durability, making them suitable for applications that require secure fastening under extreme pressure or demanding environments.

Are titanium alloy bolts lighter than other bolts?

Yes, titanium alloy bolts are significantly lighter than traditional steel bolts. The low density of titanium allows for weight reduction without compromising strength, making them especially advantageous in industries where weight savings are critical, such as aerospace and automotive.

Do titanium alloy bolts offer precise and reliable fastening?

Absolutely. Titanium alloy bolts are manufactured with utmost precision, ensuring a perfect fit and secure fastening. This precision is particularly crucial in aerospace applications, where the integrity and safety of aircraft structures depend on reliable fastening solutions.

Can titanium alloy bolts be used in industrial manufacturing?

Yes, titanium alloy bolts are widely used in industrial manufacturing. Their exceptional properties, including strength, corrosion resistance, and precision, make them suitable for various industrial applications, such as construction, oil and gas, machinery, and more.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China