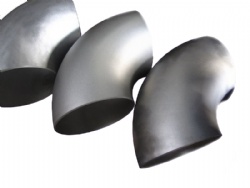

Products >> Titanium >>

Gr2 titanium tee fittings

- Product No.:2023918162239

| Dimensions of Reducing outlet Tees ASME/ANSI B16.9 | |||||||

| Nominal Pipe Size DN (in) | Outside Diameter at Bevel | Center to End | Nominal Pipe Size DN (in) | Outside Diameter at Bevel | Center to End | ||

| DlxD2 (mm) | C (mm) | M (mm) | DlxD2 (mm) | C (mm) | M (mm) | ||

| 1/2X1/2 | 21.3x21.3 | 25.4 | 3-1/2 x 3-1/2 | 101.6x101.6 | 95.3 | 95.3 | |

| l/2x3/8 | 21.3x17.1 | 3-1/ 2 x 3 | 101.6x88.9 | 91.9 | |||

| 1/2X1/4 | 21.3x13.7 | 3-1/2 x 2-1/2 | 101.6x73.0 | 88.9 | |||

| 3/4x3/4 | 26.7x26.7 | 28.4 | 3-1/2 x 2 | 101.6x60.3 | 82.6 | ||

| 3/4X1/2 | 26.7x213 | 3-1/2 x 1-1/2 | 101.6x48.3 | 79.2 | |||

| 3/4x3/8 | 26.7x17.1 | 4x4 | 114.3x114.3 | 104.6 | 104.6 | ||

| lxl | 33.4x33.4 | 38.1 | 4x3-l/2 | 114.3x101.6 | 101.6 | ||

| 1x3/4 | 33.4x26.7 | 4x3 | 114.3x88.9 | 98.6 | |||

| lxl/2 | 33.4x21.3 | 4x2-l/2 | 114.3x73.0 | 95.3 | |||

| 1-1/4X1-1/4 | 42.2x42.2 | 47.8 | 4x2 | 114.3x60.3 | 88.9 | ||

| 1-1/4X1 | 42.2x33.4 | 4 x 1-1/2 | 114.3x48.3 | 85.9 | |||

| l-l/4x3/4 | 42.2x26.7 | 5x5 | 141.3x141.3 | 124 | 124 | ||

| 1-1/4X1/2 | 42.2x21.3 | 5x4 | 141.3x114. 3 | 117.3 | |||

| 1-1/2X1-1/2 | 48.3x48.3 | 57.2 | 5 x 3-1/2 | 141.3x101.6 | 114.3 | ||

| 1-1/2X1-1/4 | 48.3x42.2 | 5x3 | 141.3x88.9 | 111.3 | |||

| 1-1/2X1 | 48.3x33.4 | 5 x 2-1/2 | 141.3x73.0 | 108 | |||

| 1-1/2X3/4 | 48.3x26.7 | 5x2 | 141.3x60.3 | 104. 6 | |||

| 1-1/2X1/2 | 48.3x213 | 6x6 | 168.3x168.3 | 142.7 | 142. 7 | ||

| 2x2 | 60.3x603 | 63.5 | 63.5 | 6x5 | 168.3x141.3 | 136. 7 | |

| 2X1-1/2 | 60.3x48.3 | 60.5 | 6x4 | 168.3x114.3 | 130 | ||

| 2X1-1/4 | 60.3x42.2 | 57.2 | 6x3-l/2 | 168.3x101.6 | 127 | ||

| 2x1 | 60.3x33.4 | 50.8 | 6x3 | 168.3x88.9 | 124 | ||

| 2x3/4 | 60.3x26.7 | 44.5 | 6x2-l/2 | 168.3x73 0 | 120.7 | ||

| 2-l/2x2-l/2 | 73.0x73.0 | 76.2 | 76.2 | 8x8 | 219.1x219.1 | 177.8 | 177.8 |

| 2-l/2x2 | 73.0x60.3 | 69.9 | 8x6 | 219.1 X168.3 | 168.1 | ||

| 2-1/2X1-1/2 | 73.0x48.3 | 66.5 | 8x5 | 219.1x141.3 | 162 1 | ||

| 2-1/2X1-1/4 | 73.0x42.2 | 63.5 | 8x4 | 219.1x114. 3 | 155.4 | ||

| 2-1/2X1 | 73.0x33.4 | 57.2 | 8x3-l/2 | 219.1x101.6 | 152.4 | ||

| 3x3 | 88.9x88.9 | 85.2 | 85.9 | 10x10 | 273.1x273.1 | 215.9 | 215.9 |

| 3x3-l/3 | 88.9x73.0 | 82.6 | 10x8 | 273.1x219.1 | 203.2 | ||

| 3x2 | 88.9x60.3 | 76.2 | 10x6 | 273.1 x 168.3 | 193.5 | ||

| 3X1-1/2 | 88.9x48.3 | 73.2 | 10x5 | 273.1X141.3 | 190.5 | ||

| 3X1-1/4 | 88.9x42.2 | 69.9 | 10x4 | 273.1X114.3 | 184.2 | ||

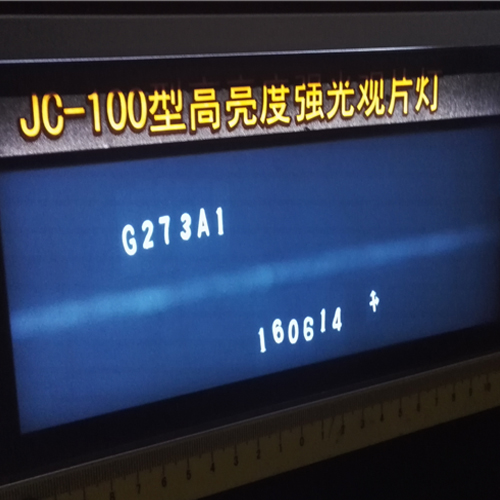

Radiographic testing, also known as radiography or X-ray inspection, is a commonly used non-destructive testing method for evaluating the integrity of welded tee fittings, including those made of titanium. It involves the use of X-rays or gamma rays to create an image of the internal structure of the fittings.

During a radiographic test, the titanium welded tee fittings are exposed to X-rays or gamma rays, which pass through the material and create an image on a film or digital detector. This image allows inspectors to examine the weld for any internal defects such as cracks, voids, or incomplete fusion.

The following is the blackness test and radiograhpic test welding seam interpreting for welded titanium fittings.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China