Products >> Titanium >>

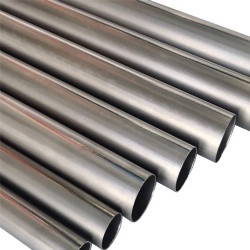

Grade 2 titanium tubes

- Product No.:2024310142342

Introduction to Titanium and GR2 Tubes

Understanding Titanium and its Properties

Overview of GR2 Titanium Tubes

Properties and Benefits of GR2 Titanium Tubes

Industrial Applications of GR2 Titanium Tubes

Advantages of Using GR2 Tubes in Various Industries

Considerations for Selecting and Working with GR2 Titanium Tubes

Case Studies: Success Stories with GR2 Titanium Tubes

Future Trends and Innovations in GR2 Tube Technology

Introduction to Titanium and GR2 Tubes

Titanium is like that underrated superhero in the materials world - strong, light, and resistant to pretty much anything trying to mess with it. GR2 Titanium Tubes are like the cool sidekick, taking all those awesome titanium properties and turning them into versatile tubes for all sorts of applications.

Understanding Titanium and its Properties

Titanium is a tough cookie with a knack for being strong, lightweight, and rust-resistant - it's basically the MacGyver of metals. Its low density makes it perfect for applications where weight matters, and its corrosion resistance means it can handle the elements like a champ.

Overview of GR2 Titanium Tubes

GR2 Titanium Tubes are like the fancy upgraded version of your regular tubes - they're made of Grade 2 titanium, which is known for its balance of strength and formability. These tubes are like the Swiss Army knives of the tubing world, ready to tackle whatever job comes their way.

Properties and Benefits of GR2 Titanium Tubes

GR2 Titanium Tubes aren't just pretty faces - they bring a whole bunch of benefits to the table that make them a go-to choice for many industries.

Corrosion Resistance and Durability

These tubes laugh in the face of rust and corrosion, making them perfect for applications where things get a little rough and tumble. They'll keep standing strong even when the elements try to bring them down.

High Strength-to-Weight Ratio

Despite being tough cookies, GR2 Titanium Tubes are surprisingly light, thanks to that low density of titanium. This means they can pack a punch without weighing you down, making them ideal for applications where weight matters.

Thermal and Conductive Properties

These tubes don't just look good - they've got the brains too. With excellent thermal and conductive properties, they can handle high temperatures and conduct heat like a pro, making them a top choice for applications where heat management is key.

Industrial Applications of GR2 Titanium Tubes

GR2 Titanium Tubes are the unsung heroes in many industries, quietly doing their job and making everything run smoother.

Aerospace and Aviation

From aircraft frames to engine components, GR2 Titanium Tubes are the go-to choice in the aerospace industry for their lightweight yet strong properties, helping planes soar through the skies with ease.

Medical and Healthcare

In the medical field, GR2 Titanium Tubes are used in implants, surgical instruments, and medical devices thanks to their biocompatibility and durability, giving patients peace of mind that they're in good hands.

Oil and Gas Industry

GR2 Titanium Tubes take on the tough job in the oil and gas industry, handling corrosive environments and high temperatures with ease. They keep things flowing smoothly in pipelines and processing plants without breaking a sweat.

Advantages of Using GR2 Tubes in Various Industries

GR2 Titanium Tubes bring a lot to the table, making them a favorite choice across different industries.

Cost Efficiency and Longevity

With their durability and corrosion resistance, GR2 Titanium Tubes are like that investment piece in your wardrobe - they last a long time, saving you money in the long run and keeping your operations smooth sailing.

Customizability and Design Flexibility

These tubes aren't just one-trick ponies - they can be shaped, welded, and customized to fit specific needs, giving industries the flexibility to get creative with their designs and push the boundaries of what's possible.

Considerations for Choosing and Working with GR2 Titanium Tubes

When it comes to GR2 titanium tubes, there are a few key considerations to keep in mind. Firstly, look for tubes manufactured using high-quality processes that adhere to industry standards. This ensures durability and reliability in your applications. Additionally, consider factors like tube dimensions, wall thickness, and corrosion resistance to choose the right tubes for your specific needs. Working with GR2 titanium tubes requires attention to detail and precision, so be sure to follow proper installation procedures and maintenance guidelines to maximize performance and longevity.

Manufacturing Processes and Quality Standards

The quality of GR2 titanium tubes depends greatly on the manufacturing processes and adherence to quality standards. Look for tubes that have undergone processes like seamless cold drawing or welding under controlled conditions to ensure structural integrity. Quality standards such as ASTM B338 for seamless and welded titanium tubes guarantee consistency and reliability in performance. By choosing tubes manufactured with precision and meeting stringent quality criteria, you can trust in the durability and efficiency of GR2 titanium tubes for your applications.

Installation and Maintenance Tips

Installing and maintaining GR2 titanium tubes requires careful attention to detail to ensure optimal performance. When installing tubes, make sure to use compatible fittings and connectors suitable for titanium to prevent corrosion and leaks. Regular inspection and cleaning are essential to prevent buildup and maintain efficiency. Additionally, be mindful of temperature and pressure limits to avoid compromising the integrity of the tubes. By following proper installation and maintenance practices, you can ensure the longevity and effectiveness of GR2 titanium tubes in your systems.

Case Studies: Success Stories with GR2 Titanium Tubes

Exploring real-world applications of GR2 titanium tubes reveals the diverse range of success stories in various industries. From aerospace and automotive to medical and marine applications, GR2 tubes have proven their versatility and reliability. Case studies showcasing the successful use of GR2 titanium tubes highlight their exceptional strength-to-weight ratio, corrosion resistance, and compatibility with different environments. By learning from these examples, you can gain insights into the potential of GR2 titanium tubes for your own projects.

Real-world Examples of GR2 Tube Applications

In the realm of real-world applications, GR2 titanium tubes have been instrumental in critical functions such as heat exchangers, hydraulic systems, and exhaust components. Their ability to withstand high temperatures, pressure, and corrosive environments makes them ideal for challenging conditions. Whether in industrial machinery, chemical processing, or medical implants, GR2 titanium tubes demonstrate exceptional performance and longevity. By studying these examples, you can envision the possibilities and benefits of incorporating GR2 titanium tubes into your own applications.

Future Trends and Innovations in GR2 Tube Technology

As technology continues to advance, so do the innovations in GR2 tube technology. The future holds exciting possibilities for the development of titanium alloys, opening doors to enhanced properties and performance. From improved strength and ductility to enhanced corrosion resistance and biocompatibility, advancements in titanium alloys promise greater versatility and efficiency in diverse applications. Additionally, emerging trends point towards new applications and growth areas for GR2 titanium tubes, expanding their reach across industries and pushing the boundaries of what is possible with this remarkable material.

Advancements in Titanium Alloys

The ongoing research and development in titanium alloys pave the way for cutting-edge advancements in GR2 tube technology. Innovations such as alloy modifications, microstructure control, and additive manufacturing techniques contribute to the improved mechanical properties and performance of titanium tubes. By harnessing these advancements, engineers and manufacturers can tailor titanium alloys to meet specific application requirements with precision and reliability. The evolution of titanium alloys continues to redefine the capabilities and potential of GR2 tubes in various sectors, driving innovation and progress in materials science.

Emerging Applications and Potential Growth Areas

Beyond traditional uses, GR2 titanium tubes are finding new applications and growth areas driven by technological advancements and market demands. Industries such as renewable energy, aerospace, and consumer electronics are increasingly turning to titanium for its unique properties and benefits. From lightweight structures and corrosion-resistant components to biocompatible implants and additive manufacturing, the potential applications of GR2 titanium tubes are expanding rapidly. By staying informed about emerging trends and exploring innovative possibilities, you can tap into the evolving landscape of GR2 tube technology and unlock new opportunities for growth and innovation.In conclusion, the versatility and exceptional properties of GR2 titanium tubes continue to revolutionize various industries, offering unmatched durability, corrosion resistance, and design flexibility. As we look ahead to future innovations and advancements in GR2 tube technology, it is clear that the potential for these remarkable tubes is limitless. Embracing the power of GR2 titanium tubes opens doors to new possibilities and ensures a bright future for industries that rely on high-performance materials.

Frequently Asked Questions

What are the key properties that make GR2 titanium tubes stand out in industrial applications?

How can businesses ensure the proper selection and maintenance of GR2 titanium tubes for optimal performance?

Are there specific industries or sectors that benefit most from utilizing GR2 titanium tubes, and why?

What are some upcoming trends and innovations in GR2 tube technology that industry professionals should be aware of?

Previous Product:titanium pipes

Next Product:Gr5 titanium alloy rods

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China