Products >> Molybdenum >>

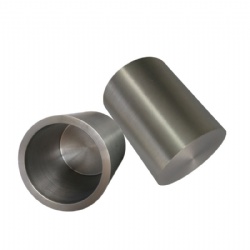

Molybdenum crucibles sizes

- Product No.:2023122172642

Molybdenum Crucibles: The Enduring Vessels for High-Temperature Applications

Molybdenum crucibles are one of the most sought-after vessels for high-temperature applications. They are ideal for use in a wide range of industries for their unique properties that make them suitable for enduring high temperatures and extreme conditions.

Whether you are in the metallurgy, semiconductor, or chemical industry, molybdenum crucibles are the perfect solution for your high-temperature needs. In this article, we'll explore the benefits of molybdenum crucibles and how they can be used for various applications.

Key Takeaways:

- Molybdenum crucibles are suitable for high-temperature applications.

- They are commonly used in industries such as metallurgy, semiconductor, and chemical.

- Molybdenum crucibles have unique properties that make them ideal for enduring high temperatures and extreme conditions.

- Different sizes of molybdenum crucibles are available depending on specific application requirements.

- Molybdenum crucibles are an enduring choice due to their excellent thermal conductivity and resistance to thermal shock.

Where to Buy Molybdenum Crucibles

If you are looking to buy molybdenum crucibles, there are several options available. These include online retailers, manufacturers, and specialized suppliers. Let's take a closer look at each of these options.

Online Retailers

Many online retailers offer molybdenum crucibles for sale. These retailers often have a wide range of sizes and purities available, making it easy to find the right crucible for your needs. Some popular online retailers that offer molybdenum crucibles include Amazon, eBay, and Alibaba.

Manufacturers

Molybdenum crucible manufacturers are another excellent source for purchasing molybdenum crucibles. By purchasing directly from the manufacturer, you can often get a better price and ensure that you are getting a high-quality product. Some popular molybdenum crucible manufacturers include H.C. Starck, Plansee, and Thermo Fisher Scientific.

Specialized Suppliers

Specialized suppliers are another option for purchasing molybdenum crucibles. These suppliers often have a deep understanding of the unique properties and characteristics of molybdenum crucibles, making them a great resource for finding the right crucible for your specific needs. Some popular specialized suppliers of molybdenum crucibles include Midwest Tungsten Service and Ted Pella, Inc.

When purchasing molybdenum crucibles, it is important to consider factors such as size, purity, and cost. By researching your options and choosing a reputable supplier, you can ensure that you are getting a high-quality product that meets your needs.

Cost of Molybdenum Crucibles

Molybdenum crucibles are a reliable choice for high-temperature applications due to their durability and resistance to thermal shock. However, the cost of molybdenum crucibles can vary significantly depending on several factors.

One crucial factor that influences the cost of molybdenum crucibles is their size. Larger crucibles require more material and time to manufacture, resulting in a higher cost. On the other hand, smaller crucibles may be less expensive but may not be suitable for all applications.

Purity is another critical factor that affects the cost of molybdenum crucibles. High-purity molybdenum is more expensive than lower purity levels. Crucibles with high purity levels are necessary for certain applications, such as crystal growth and semiconductor fabrication.

The manufacturing process also affects the cost of molybdenum crucibles. Molybdenum crucibles fabricated in complex shapes or with high precision may cost more. Additionally, the use of additional materials, such as binders or additives, may increase the production cost.

Overall, the cost of molybdenum crucibles ranges from several hundred to thousands of dollars, depending on the specified requirements. It is essential to consider the factors that affect cost when choosing a crucible for high-temperature applications to ensure optimal performance and cost-effectiveness.

Different Sizes of Molybdenum Crucibles

Molybdenum crucibles come in a variety of sizes to suit different applications. Choosing the right size is essential to ensure that the crucible performs efficiently and effectively. The size of the crucible also impacts the amount of material it can hold, which can affect the productivity of a process.

Here are some common sizes of molybdenum crucibles:

| Size (mm) | Max Volume (mL) |

|---|---|

| 20 x 20 | 8 |

| 25 x 25 | 15 |

| 30 x 30 | 27 |

| 40 x 40 | 64 |

| 50 x 50 | 125 |

It is important to note that the size of the molybdenum crucible does not only refer to the diameter or width but also to the height. The height of the crucible can impact the saturation of the material and the rate of evaporation. Therefore, the depth of the crucible should also be considered when selecting a size.

When selecting a size, it is crucial to consider the specific requirements of the process. For instance, a small crucible may be suitable for laboratory experiments while a large crucible may be necessary for industrial-scale processes. Additionally, the type of material being used can also influence the size of the crucible needed.

In summary, the right size of molybdenum crucible is crucial for achieving optimal results in high-temperature applications. Careful consideration of the specific requirements of the process is necessary when selecting the appropriate size.

How to Use Molybdenum Crucibles

Using molybdenum crucibles is a straightforward process, but it's important to follow certain guidelines to ensure optimal performance and longevity. Here's a step-by-step guide on how to use molybdenum crucibles:

- Preparation: Before using the crucible, make sure it's clean and free from any impurities or contaminants. You can clean it by soaking it in a mixture of water and a mild detergent, then rinsing it thoroughly with clean water and drying it with a lint-free cloth.

- Loading: Once the crucible is clean, you can load it with the desired material. Make sure you don't overload it, as this can cause cracking or other damage. Use a tool to gently tap the material into the crucible, ensuring it's evenly distributed.

- Heating: Place the crucible in the heating apparatus and begin heating it gradually. Don't expose it to sudden temperature changes or extreme temperatures, as this can cause thermal shock and compromise its integrity.

- Cooling: Once you're done with the material, gradually cool down the crucible to avoid thermal shock. You can do this by turning off the heating apparatus and letting the crucible cool down naturally. Never quench the crucible in water or any other liquid.

- Maintenance: After use, clean the crucible again using the same method mentioned above. Store it carefully in a dry and clean place, away from any potential contaminants or abrasive materials.

By following these simple steps, you can ensure the longevity and optimal performance of your molybdenum crucibles.

Safety Precautions for Handling Molybdenum Crucibles

When working with molybdenum crucibles, it is essential to follow proper safety precautions to prevent injury and ensure the longevity of the crucibles. Here are some guidelines to keep in mind:

Wear Protective Gear

Always wear appropriate personal protective equipment when handling molybdenum crucibles. This includes safety glasses, gloves, and heat-resistant clothing.

Handle with Care

Molybdenum crucibles are fragile and can crack or break easily. Avoid dropping or knocking them against hard surfaces. Always handle them with care.

Use Appropriate Tools

Use specialized tools, such as tongs or cradles, to handle molybdenum crucibles during loading and unloading. Never use forceps or pliers, as they can damage the crucible.

Avoid Exposure to Chemicals

Molybdenum crucibles can react with certain chemicals, such as acids or alkalis, resulting in the formation of hazardous gases. Always check the compatibility of the crucible with the substances it will come into contact with.

Proper Storage and Handling

Store molybdenum crucibles in a clean, dry area. Avoid stacking them to prevent damage. When transporting them, use a secure container to prevent bumps and breakage.

Dispose of Properly

Molybdenum crucibles should be disposed of properly according to local regulations. Do not dispose of them with regular waste.

By following these safety precautions, you can ensure the safe and effective use of molybdenum crucibles in high-temperature applications.

Molybdenum Crucibles vs. Ceramic Crucibles

Choosing between molybdenum and ceramic crucibles is a common dilemma in high-temperature applications. Let's take a closer look at the advantages and disadvantages of each material.

Molybdenum Crucibles

Molybdenum crucibles are known for their high melting point, excellent thermal conductivity, and resistance to thermal shock. They are strong, durable, and long-lasting, making them suitable for repeated use in extreme conditions. Molybdenum crucibles are ideal for use in high-temperature applications where purity and chemical resistance are critical. They are particularly useful in the production of high-purity metals, alloys, and semiconductors.

Ceramic Crucibles

Ceramic crucibles are lightweight and come in many different shapes and sizes. They are more affordable compared to molybdenum crucibles, making them a popular choice for budget-conscious consumers. Ceramic crucibles are also useful for applications that require good thermal shock resistance and chemical stability. They are ideal for use in low-temperature applications where high purity is not a primary concern.

| Material | Advantages | Disadvantages |

|---|---|---|

| Molybdenum Crucibles | High melting point, excellent thermal conductivity, resistance to thermal shock, suitable for high-temperature applications | More expensive, less variety in shapes and sizes compared to ceramic crucibles |

| Ceramic Crucibles | Lightweight, more affordable, good thermal shock resistance, chemical stability | Less durable, less suitable for high-temperature applications compared to molybdenum crucibles |

"Molybdenum crucibles are the go-to choice for high-temperature applications where purity and chemical resistance are critical, while ceramic crucibles are more affordable and useful for low-temperature applications."

When deciding between molybdenum crucibles and ceramic crucibles, it's essential to consider the specific application's requirements. Both materials have their advantages and disadvantages, depending on the particular use case. Consulting with a knowledgeable supplier can help make an informed decision that meets the specific needs of the application.

Molybdenum Crucibles vs. Graphite Crucibles

When it comes to selecting the right crucible for high-temperature applications, molybdenum and graphite are two commonly used materials. While both have their advantages and disadvantages, it is essential to understand the unique properties of each when deciding which material to use.

Performance

In terms of performance, molybdenum crucibles have a higher melting point than graphite crucibles. Molybdenum has a melting point of 2,620°C, while graphite has a melting point of 3,369°C, making molybdenum more suitable for high-temperature applications.

While graphite crucibles have a lower melting point, they have excellent thermal shock resistance and can withstand rapid temperature changes without cracking. On the other hand, molybdenum crucibles are more brittle and can crack when exposed to thermal shock.

Durability

Graphite crucibles are generally less expensive than molybdenum crucibles, but they have a shorter lifespan. Graphite crucibles tend to wear out faster than molybdenum crucibles, especially when exposed to high temperatures.

Molybdenum crucibles are more durable and can last for multiple uses when handled correctly. They are less prone to wear and tear and can withstand repeated heating and cooling cycles.

Temperature Range

While both materials are suitable for high-temperature applications, they have different temperature ranges. Graphite crucibles are ideal for temperatures ranging from 500°C to 3,000°C, while molybdenum crucibles are suitable for temperatures ranging from 1,100°C to 2,200°C.

Molybdenum Crucibles vs. Quartz Crucibles

When it comes to high-temperature applications, molybdenum crucibles and quartz crucibles are two popular options. Both materials offer unique advantages and disadvantages depending on the specific needs of the application.

Molybdenum Crucibles: Molybdenum crucibles are highly durable and can withstand extreme temperatures, making them an ideal choice for applications that require high thermal stability. They also have excellent thermal conductivity, allowing for efficient heating and melting of materials. In addition, molybdenum crucibles have a low coefficient of thermal expansion, which helps minimize thermal stress during heating and cooling cycles.

Quartz Crucibles: Quartz crucibles are known for their exceptional purity and transparency, making them a great choice for applications that require an inert and non-reactive material. They have a high resistance to thermal shock, which enables them to withstand rapid temperature changes without cracking or breaking. Quartz crucibles are also relatively lightweight and can be easily shaped into various sizes and geometries.

Overall, the choice between molybdenum crucibles and quartz crucibles will depend on the specific requirements of the application. Factors such as temperature range, material purity, and thermal stress resistance should all be taken into consideration when selecting the appropriate crucible material.

Exploring the Enduring Properties of Molybdenum Crucibles

Molybdenum crucibles are an exceptional option for high-temperature applications due to their unique properties, which enable them to withstand extreme conditions while maintaining their structural integrity. The following are the enduring properties that make molybdenum crucibles so exceptional:

High Melting Point

Molybdenum has an exceptionally high melting point of 2,623°C, an attribute that makes it one of the most heat-resistant metals on earth. As a result, molybdenum crucibles can withstand the most extreme temperatures in high-temperature applications.

Resistance to Thermal Shock

Molybdenum crucibles are also capable of withstanding rapid temperature changes, a quality that is crucial in high-temperature applications where temperature changes can occur quickly and frequently. Molybdenum has a very low coefficient of thermal expansion, which means that it expands and contracts very little in response to temperature changes, making it resistant to thermal shock.

Excellent Thermal Conductivity

Molybdenum crucibles have excellent thermal conductivity, which enables them to transmit heat evenly throughout the crucible. This attribute is critical in high-temperature applications where temperature uniformity is crucial for the successful outcome of the process.

High Corrosion Resistance

Molybdenum crucibles are highly resistant to corrosion by acids, alkalis, and molten metals. This is due to the fact that molybdenum forms very stable oxides, sulfides, and carbides that protect the metal from corrosion.

High Strength and Rigidity

Molybdenum has a high strength-to-weight ratio, which makes it very strong and rigid despite its low density. This attribute makes molybdenum crucibles particularly suitable for high-temperature applications where mechanical strength and rigidity are crucial.

In conclusion, molybdenum crucibles are exceptional vessels for high-temperature applications due to their unique features and benefits. Their high melting point, resistance to thermal shock, excellent thermal conductivity, high corrosion resistance, and high strength and rigidity make them ideal for enduring extreme temperatures and conditions.

Applications of Molybdenum Crucibles

Molybdenum crucibles are versatile vessels that have a wide range of applications in high-temperature environments. Their exceptional ability to withstand extreme temperatures and resist corrosion makes them ideal for use in various industrial processes.

Here are some of the most common applications of molybdenum crucibles:

- Czochralski (CZ) method for crystal growth: In the CZ method, molybdenum crucibles are used to melt and solidify silicon to produce high-quality single-crystal silicon ingots. The uniformity and purity of the crucibles make it possible to obtain high-quality crystals with minimal defects.

- Metal melting: Molybdenum crucibles are widely used to melt metals, such as gold, silver, platinum, and other precious metals, due to their high melting point and excellent thermal conductivity. They are also used in the production of specialty alloys and superalloys.

- Chemical analysis: Molybdenum crucibles are used in high-temperature chemical analysis processes, such as X-ray fluorescence and atomic absorption spectroscopy. They offer excellent resistance to acidic and alkaline solutions, making them ideal for use in harsh chemical environments.

- Heat treatment: Molybdenum crucibles are used in heat treatment processes for metals and ceramics. They provide high-temperature stability and uniform heating, making it possible to achieve consistent results.

- Electronics manufacturing: Molybdenum crucibles are used in the production of electronic components, such as capacitors and transistors. Their excellent electrical conductivity and thermal properties make them ideal for use in high-temperature vacuum environments.

From crystal growth to electronics manufacturing, molybdenum crucibles are essential vessels for a wide range of high-temperature applications. Their unique properties make them an excellent choice for industries that require high-performance materials that can withstand extreme conditions.

Conclusion

To sum up, molybdenum crucibles are a reliable and durable option for high-temperature applications. Their enduring properties, such as high melting point, resistance to thermal shock, and excellent thermal conductivity, make them a preferred choice for many industries.

When purchasing molybdenum crucibles, it is essential to consider factors such as size, purity, and specific application needs. It is also crucial to follow proper safety precautions when handling the crucibles to avoid potential hazards.

Overall, molybdenum crucibles provide a versatile solution for a range of applications, including crystal growth, metal melting, and chemical analysis. By selecting the right size and quality crucibles and following proper handling guidelines, users can maximize the benefits of this enduring vessel.

FAQ

Where can I buy molybdenum crucibles?

Molybdenum crucibles can be purchased from online retailers, specialized suppliers, and manufacturers.

What factors influence the cost of molybdenum crucibles?

The cost of molybdenum crucibles is influenced by factors such as size, purity, and the manufacturing process.

What sizes of molybdenum crucibles are available?

Molybdenum crucibles are available in various sizes. It is important to choose the right size for your specific application.

How do I use molybdenum crucibles?

To use molybdenum crucibles effectively, follow a step-by-step guide that includes tips for preparation, loading, and maintaining the crucibles.

What safety precautions should I take when handling molybdenum crucibles?

It is important to follow safety precautions when working with molybdenum crucibles. This includes guidelines for safe handling and addressing potential hazards.

How do molybdenum crucibles compare to ceramic crucibles?

Molybdenum crucibles and ceramic crucibles have their advantages and disadvantages for specific applications. We will discuss these differences in this section.

How do molybdenum crucibles compare to graphite crucibles?

Molybdenum crucibles and graphite crucibles differ in terms of performance, durability, and suitability for different temperature ranges. We will explore these differences in this section.

How do molybdenum crucibles compare to quartz crucibles?

Molybdenum crucibles and quartz crucibles have their strengths and weaknesses when used in high-temperature applications. We will compare these properties in this section.

What are the enduring properties of molybdenum crucibles?

Molybdenum crucibles possess unique properties such as a high melting point, resistance to thermal shock, and excellent thermal conductivity. We will explore these properties in detail.

What are the common applications of molybdenum crucibles?

Molybdenum crucibles are commonly used in crystal growth, metal melting, and chemical analysis applications. We will discuss these applications in this section.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China