Titanium alloy and types of titanium alloy

Titanium alloy: are metallic materials that are primarily composed of titanium along with other elements such as aluminum, vanadium, iron, and others. These alloys are engineered to have specific properties and characteristics to suit various applications across industries like aerospace, automotive, medical, and more.

Here are a few common types of titanium alloys:

|

Types of Titanium Alloy |

Examples of Titanium Alloy |

|

Alpha Titanium Alloy |

Ti/Pd Alloys – ASTM grades 7 and 11 |

|

Near Alpha Titanium Alloys |

Ti-8%Al-1%Mo-1%V |

|

Alpha-Beta Titanium Alloys |

Ti-6%Al-4%V |

- 1. Ti-6Al-4V (Grade 5): This is the most widely used titanium alloy, composed of 90% titanium, 6% aluminum, and 4% vanadium. It offers a good balance of strength, corrosion resistance, and weldability. It is commonly used in aerospace components, biomedical implants, and high-performance parts.

- 2. Ti-3Al-2.5V (Grade 9): This alloy contains 90% titanium, 3% aluminum, and 2.5% vanadium. It has excellent corrosion resistance and high strength, making it suitable for applications where weight reduction is crucial, such as aircraft components and sports equipment.

- 3. Ti-6Al-6V-2Sn: Composed of 90% titanium, 6% aluminum, 6% vanadium, and 2% tin, this alloy offers exceptional high-temperature strength and corrosion resistance. It is often used in gas turbine engine components and other high-stress applications.

- 4. Ti-5Al-2.5Sn (Grade 6): This alloy consists of 90% titanium, 5% aluminum, and 2.5% tin. It exhibits excellent weldability and is often utilized in marine and chemical processing applications due to its resistance to saltwater corrosion.

- 5. Ti-6Al-2Sn-4Zr-2Mo: This alloy contains 88% titanium, 6% aluminum, 2% tin, 4% zirconium, and 2% molybdenum. It offers exceptional tensile strength, high-temperature stability, and corrosion resistance. It is commonly used in aerospace applications, particularly for engine components.

- 6. Ti-Pd (Grade 7) is a titanium alloy that contains 99.2% pure titanium along with small amounts of palladium (0.12-0.25%). Grade 7 titanium is known for its excellent corrosion resistance in reducing and oxidizing environments, including seawater.

These are just a few examples of titanium alloys, and there are various other types available with different compositions and properties, each designed to meet specific requirements in different industries. The selection of the right titanium alloy depends on factors such as desired strength, corrosion resistance, temperature range, and cost-effectiveness for a particular application.

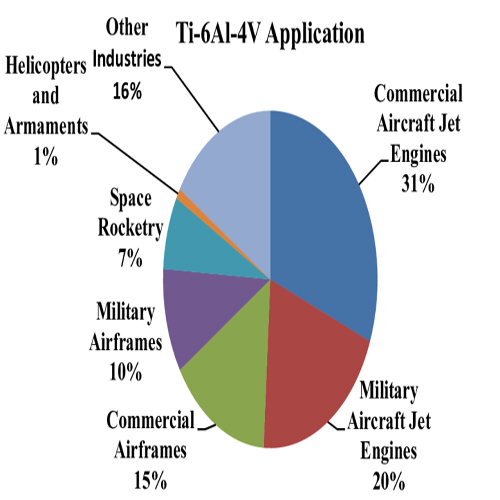

Titanium alloy Gr5 applications:

Titanium alloys are metallic materials comprised of titanium as the primary element, combined with other elements such as aluminum, vanadium or nickel. Titanium alloys are known for their superior strength-to-weight ratio, corrosion resistance and high temperature performance - all key qualities found in today's competitive business environments. Applications where titanium alloys are often employed:

1. Aerospace Industry: Titanium alloys have long been utilized by aircraft components manufacturers, from structural parts, engine components, landing gear and fasteners to lightweight fuel efficient components and fasteners. Their lightweight properties help improve fuel efficiency while simultaneously decreasing overall weight while their strength guarantees structural integrity.

2. Medical Implants: Titanium alloys are biocompatible materials, meaning that they do not cause adverse reactions in humans when in contact with them. Titanium implants are widely used in joint replacements, dental implants, and bone plates due to their corrosion-resistance and ability to integrate with natural bone structure.

3. Marine and Offshore Industry: Titanium alloys have long been utilized in marine applications due to their excellent resistance to seawater corrosion, including ship hulls, propellers, offshore oil & gas platforms and underwater structures.

4. Chemical Processing: Titanium alloys have superior corrosion resistance, making them the perfect material choice for equipment used in chemical processing plants. Reactors, heat exchangers, valves and piping systems employing titanium alloys can safely handle chemicals that contain harmful substances without corrosion being an issue.

5. Titanium alloys have numerous applications in sports equipment, particularly high-performance bicycles, golf clubs, tennis rackets and other lightweight sporting goods. Their strength and durability contribute to improved performance and extended life span of these lightweight sporting goods.

6. Automotive Industry: Titanium alloys have long been utilized by automakers to reduce weight, including exhaust systems, suspension springs and connecting rods. Their excellent strength-to-weight ratio contributes to better fuel economy and vehicle performance.

Latest News

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China