Dimension, tolerance and bevelling for Titanium Pipe Fittings

Before you buy titanium pipe fittings, the basic knowledge you should know is Titanium fittings dimension, tolerance, material grade, bevelling.

Titanium Pipe Fittings Dimensions:

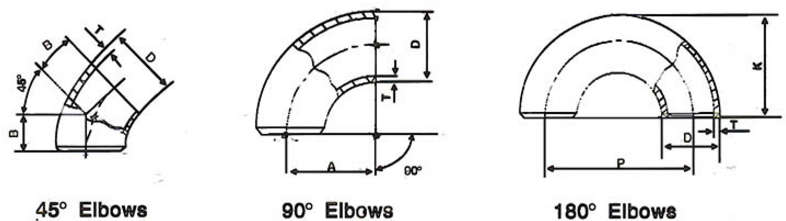

| Dimensions of Titanium Elbows and Returns ASME/ANSI B16.9 | ||||||||

| Nominal Pipe Size (NPS) | Outside Diameter Bevel D | Center to End | Center to Center | Back to Faces | ||||

| 45° Elbows | 90° Elbows | 180° Elbows | ||||||

| B | A | P | K | |||||

| Long Radius | Long Radius | Short Radius | Long Radius | Long Radius | Long Radius | Long Radius | ||

| 1/2 | 21.3 | 15.7 | 38.1 | / | 76.2 | / | 47.8 | / |

| 3/4 | 26.7 | 19.1 | 38.1 | / | 76.2 | / | 50.8 | / |

| 1 | 33.4 | 22.4 | 38.1 | 25.4 | 76.2 | 50.8 | 55.6 | 41.1 |

| 1-1/2 | 42.2 | 25.4 | 47.8 | 31.8 | 953 | 63.6 | 69.9 | 52.3 |

| 1-3/4 | 48.3 | 28.4 | 57.2 | 38.1 | 114.3 | 76.2 | 82.6 | 62 |

| 2 | 60.3 | 35.1 | 76.2 | 50.8 | 152.4 | 101.6 | 106.4 | 51 |

| 2-1/2 | 70.3 | 44.5 | 95.3 | 63.5 | 190.5 | 127 | 131.8 | 100.1 |

| 3 | 88.9 | 50.8 | 114.3 | 76.2 | 228.6 | 152.4 | 158.8 | 120.7 |

| 3-1/2 | 101.6 | 57.2 | 133.4 | 88.9 | 266.7 | 177.8 | 184.2 | 139.7 |

| 4 | 1143 | 63.5 | 152.4 | 101.6 | 304.8 | 203 | 209.6 | 158.8 |

| 5 | 141.3 | 19.2 | 190.5 | 127 | 381 | 254 | 261.9 | 196.9 |

| 6 | 1683 | 95.3 | 228.6 | 152.4 | 457.2 | 304.8 | 312.7 | 236.5 |

| 8 | 219.1 | 127 | 304.8 | 203.2 | 609.6 | 406.4 | 414.3 | 312.7 |

| 10 | 273.1 | 158.8 | 381 | 254 | 762 | 508 | 517.7 | 390.7 |

| 12 | 323.9 | 190.5 | 457.2 | 304.8 | 914.4 | 609.6 | 619.3 | 466.9 |

| 14 | 355.6 | 222.3 | 533.4 | 355.6 | 1066.8 | 711.2 | 711.2 | 533.4 |

| 16 | 406.4 | 254 | 609.6 | 406.4 | 1219.2 | 812.8 | 812.8 | 609.6 |

| 20 | 508 | 317.5 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 558.8 | 342.9 | 838.2 | 558.8 | 1676.4 | 1117.6 | 1117.6 | 838.2 |

| 24 | 609.6 | 381 | 914.4 | 609.6 | 1828.8 | 1219.2 | 1219.2 | 914.4 |

| 26 | 660.4 | 406 | 990.6 | / | / | / | / | / |

| 28 | 711.2 | 438.2 | 1066.8 | / | / | / | / | / |

| 30 | 762 | 469.9 | 1143 | / | / | / | / | / |

| 32 | 812.8 | 501.7 | 1219.2 | / | / | / | / | / |

| 34 | 863.6 | 533.4 | 1295.4 | / | / | / | / | / |

| 36 | 914.4 | 565.2 | 1371.6 | / | / | / | / | / |

| 38 | 965.2 | 599.9 | 1447.8 | / | / | / | / | / |

| 40 | 1016 | 632 | 1524 | / | / | / | / | / |

| 42 | 1066.8 | 660.4 | 1600.2 | / | / | / | / | / |

| 44 | 1117.6 | 695.5 | 1676.4 | / | / | / | / | / |

| 46 | 1168.4 | 726.9 | 1752.6 | / | / | / | / | / |

| 48 | 1219.2 | 758.9 | 1828.8 | / | / | / | / | / |

Titanium Pipe Fittings Material Grade

| Titanium Pipe Fittings Chemical Composition | |||||||

| CHEMICAL COMPOSITION | ASTM B363 | ||||||

| (Max. Values) | WPT-1 | WPT-2 | WPT-5 | WPT-7 | WPT-9 | WPT-12 | WPT-23 |

| N. Nitrogen | 0.03 | 0.03 | 0.05 | 0.03 | 0.02 | 0.03 | 0.03 |

| C. Carbon | 0.1 | 0.1 | 0.1 | 0.1 | 0.05 | 0.08 | 0.08 |

| H. Hydrogen | 0.015 | 0.015 | 0.0125 | 0.015 | 0.013 | 0.015 | 0.0125 |

| Fe. Iron | 0.2 | 0.3 | 0.4 | 0.3 | 0.25 | 0.3 | 0.25 |

| O. Oxygen | 0.18 | 0.25 | 0.2 | 0.25 | 0.12 | 0.25 | 0.13 |

| Pd. Palladium | 0.12-0.25 | ||||||

| Al. Aluminum | 5.5-6.75 | 2.5-3.5 | 5.5-6.5 | ||||

| Mo. Molybdenum | 0.2-0.4 | ||||||

| V. Vanadium | 3.5-4.5 | 2.0-3.0 | 3.5-4.5 | ||||

| Ni. Nickel | 0.6-0.9 | ||||||

| Ti. Titanium | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. |

Titanium Pipe Fittings Tolerance:

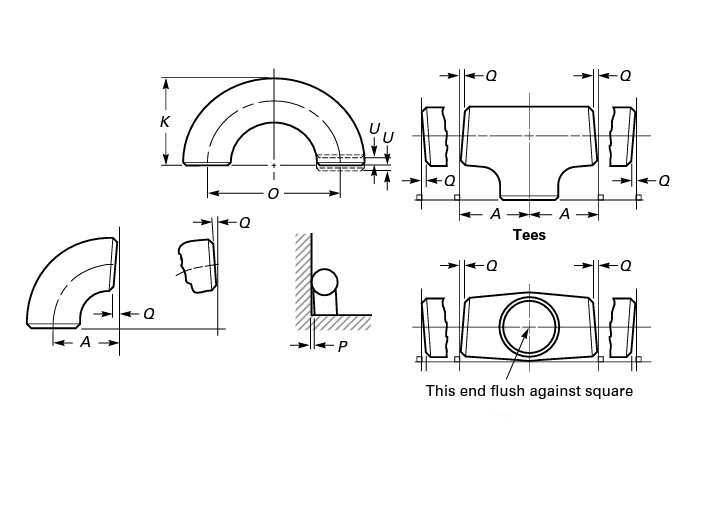

1. General tolerance for all titanium pipe fittings of ASME B16.9

|

NPS |

DN |

O.D |

I.D |

Off Angle, Q |

Off Plane, P |

|

1/2~2-1/2 |

15~65 |

+1.6, -0.8 |

±0.8 |

±1 |

±2 |

|

3~3-1/2 |

80~90 |

±1.6 |

±1.6 |

±2 |

±4 |

|

4 |

100 |

±1.6 |

±1.6 |

±3 |

±5 |

|

5~8 |

125~200 |

+2.4, -1.6 |

±1.6 |

±3 |

±6 |

|

10~18 |

250~450 |

+4.0, -3.2 |

±3.2 |

±4 |

±10 |

|

20~24 |

500~600 |

+6.4, -4.8 |

±4.8 |

±5 |

±10 |

|

26~30 |

650~750 |

+6.4, -4.8 |

±4.8 |

±5 |

±13 |

|

32~48 |

800~1200 |

+6.4, -4.8 |

±4.8 |

±5 |

±19 |

*All dimensions are in mm unit. NPS: Nominal Pipe Size; DN: Nominal Diameter.

*O.D: outside diameter at bevel; I.D: inside diameter at end; Both P & Q are angularity tolerances.

*A minimum wall thickness of 87.5% should apply unless otherwise specified by the purchaser.

2. Tolerances of Center-to-End & Overall Length Dimensions

|

NPS |

DN |

*I |

*II |

*III |

*IV |

|

1/2~2-1/2 |

15~65 |

±2 |

±3 |

±2 |

±3 |

|

3~3-1/2 |

80~90 |

±2 |

±3 |

±2 |

±3 |

|

4 |

100 |

±2 |

±3 |

±2 |

±3 |

|

5~8 |

125~200 |

±2 |

±3 |

±2 |

±6 |

|

10~18 |

250~450 |

±2 |

±3 |

±2 |

±6 |

|

20~24 |

500~600 |

±2 |

±3 |

±2 |

±6 |

|

26~30 |

650~750 |

±3 |

±6 |

±5 |

±10 |

|

32~48 |

800~1200 |

±5 |

±6 |

±5 |

±10 |

*All dimensions are in mm unit.

*I refers to the tolerances for center-to-end dimensions of 90° & 45° long and short radius elbows and tees, A, B, C, M.

*II refers to the tolerances for center-to-end dimensions of 3D radius elbows, A, B.

*III refers to the tolerances for overall length of reducers and lap joint stub ends, F, H.

*IV refers to the tolerances for overall length of caps, E.

3. Tolerances for 180° Returns & Lap Joint Stub Ends

|

NPS |

DN |

180° Return |

Lap Joint Stub Ends |

||||

|

inch |

mm |

O |

K |

U |

G |

R |

T |

|

1/2~2-1/2 |

15~65 |

±6 |

±6 |

±1 |

+0, -1 |

+0, -1 |

+1.6, -0 |

|

3~3-1/2 |

80~90 |

±6 |

±6 |

±1 |

+0, -1 |

+0, -1 |

+1.6, -0 |

|

4 |

100 |

±6 |

±6 |

±1 |

+0, -1 |

+0, -2 |

+1.6, -0 |

|

5~8 |

125~200 |

±6 |

±6 |

±1 |

+0, -1 |

+0, -2 |

+1.6, -0 |

|

10~18 |

250~450 |

±10 |

±6 |

±2 |

+0, -2 |

+0, -2 |

+3.2, -0 |

|

20~24 |

500~600 |

±10 |

±6 |

±2 |

+0, -2 |

+0, -2 |

+3.2, -0 |

*All dimensions are in mm unit.

*O: center-to-center dimensions; K: back-to-face dimensions; U: alignment of ends.

*G: outside diameter of lap; R: fillet radius of lap; T: Lap thickness.

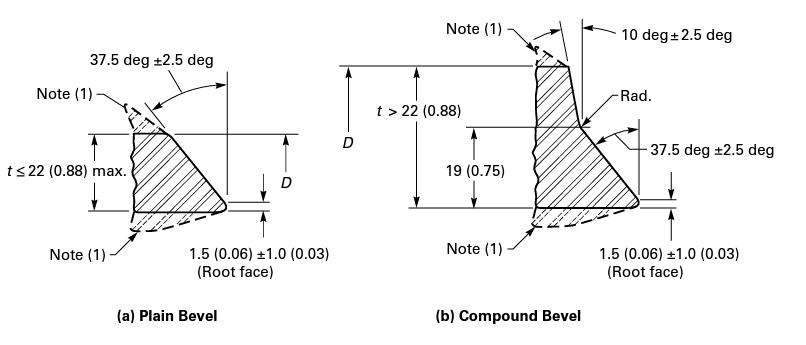

Titanium Pipe Fittings Bevelling

There are three types of ends for titanium pipe fittings, they are flat ends, plain bevelling ends and compound bevelling ends. the bevellings are classified by wall thickness for ttanium pipe fittings.

1. for titanium pipe fittings wall thickness less than 3mm, titanium pipe fittings can be supplied with flat ends.

2. for wall thickness 3mm-22mm, titanium pipe fittings supplied with 37.5 degrees bevelling at ends with 1.5mm root face.

3. for wall thickness more than 22mm, titanium pipe fittings supplied with 10 deg. and 37.5 deg, bevelling with 1.5mm root face

Latest News

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China