Titanium pipe fittings for desalination

Commercially pure titanium pipe fittings, Grade 1, Grade 2, Grade 3, exhibits excellent corrosion resistance to seawater at temperatures less than 130°C

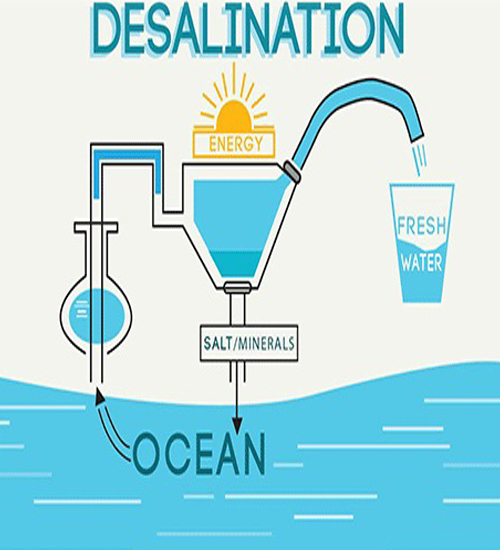

Desalination industry: Titanium pipe fittings are employed in desalination plants for converting seawater into fresh water. Titanium's corrosion resistance and low fouling characteristics make it an ideal choice for this application.

Titanium's properties make it well-suited for desalinating seawater. Here are some specific properties of titanium that contribute to its effectiveness in this application:

Good corrosion resistance: Titanium pipe fittings' high resistance to corrosion, particularly in oxidizing and neutral media, makes it ideal for desalination plants where seawater is the primary source. The dense and inert oxide film formed on the surface of titanium protects it from corrosion.

Low-temperature performance and resistance: Titanium pipe fittings retains its strength and plasticity even at low temperatures. This is important in desalination processes that may involve temperature fluctuations.

Low density, high specific strength: Titanium pipe fittings has a low density compared to other metals such as steel and copper, but its specific strength (strength-to-weight ratio) is remarkably high. This makes it a lightweight yet strong choice for desalination equipment.

Excellent heat resistance: Certain titanium pipe fittings alloys can withstand high temperatures, making them suitable for long-term use in desalination plants where heat is involved, such as in the evaporation or condensation processes.

Enhanced heat exchange performance: Despite having lower thermal conductivity compared to materials like carbon steel and copper, titanium's corrosion resistance allows for thinner walls, improving heat transfer efficiency. This is achieved through dropwise condensation, which reduces thermal resistance.

Desalination is a significant method used in water-scarce areas like the Middle East to obtain fresh water. Titanium pipe fittings plays a crucial role in desalination equipment, specifically in heat exchangers and pipes. The multi-stage flash method is commonly used for desalination, involving various components such as water heating equipment, condensers, compressors, and heat exchange tubes. Titanium tubes are preferred over copper alloy tubes due to their superior corrosion resistance. Plate heat exchangers also utilize titanium or titanium alloys for their materials, providing excellent resistance to corrosion. The use of titanium in desalination equipment is driven by its ability to withstand high temperatures and resist corrosion from sea salts and chlorides. Industrial pure titanium (ASTMGrade2) is widely used, along with other specialized grades for specific applications. Additionally, titanium-clad steel plates can reduce costs while meeting performance requirements. The development of corrosion-resistant titanium alloys for marine engineering further expands the potential applications in desalination. Plate heat exchangers are commonly used in desalination devices, offering efficient vapor-liquid and liquid-liquid heat transfer options. As the demand for coastal fresh water increases, especially with large-scale installations, the development and production of desalination technologies will contribute to the growth of the titanium industry.

Latest News

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China