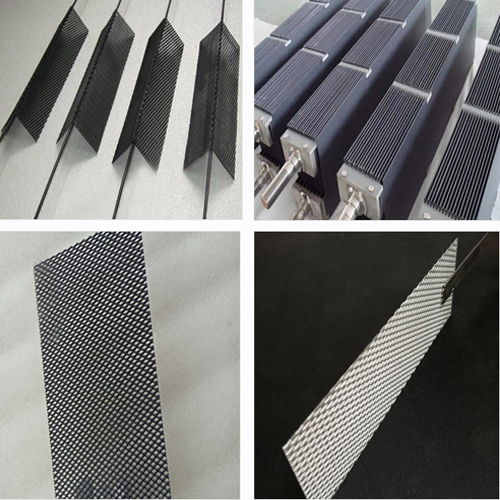

MMO Titanium electrodes Used in Chlor-Alkali Industry

MMO titanium electrodes, also known as Mixed Metal Oxide titanium electrodes, are commonly used in the chlor-alkali industry. The chlor-alkali industry involves the production of chlorine, caustic soda (sodium hydroxide), and hydrogen by the electrolysis of brine (a solution of sodium chloride).

The use of MMO titanium electrodes in this industry offers several advantages:

1, Corrosion resistance: MMO titanium electrodes have excellent corrosion resistance, preventing degradation and extending the electrode's lifespan. The corrosive nature of the electrolytes used in the chlor-alkali process can be highly damaging to traditional electrodes, but MMO titanium electrodes can withstand these aggressive environments.

2. High efficiency: MMO coatings on titanium electrodes have a catalytic effect, which improves the overall electrolysis efficiency. This results in reduced energy consumption and increased productivity in the chlor-alkali process.

3. Uniform current distribution: The MMO coating on titanium electrodes ensures uniform current distribution across the electrode surface. This helps maintain stable and consistent production rates, contributing to the overall efficiency of the electrolysis process.

4. Longevity: MMO titanium electrodes have a longer operational life compared to traditional electrodes, reducing downtime and maintenance costs. This is due to their corrosion resistance and robust construction.

5. Environmental friendliness: The use of MMO titanium electrodes reduces the need for hazardous materials such as mercury that were traditionally used in chlor-alkali electrolysis cells. This makes the process more environmentally friendly by minimizing the risk of pollution and the release of toxic substances.

Overall, MMO titanium electrodes play a critical role in the chlor-alkali industry by enabling efficient and sustainable production processes. They offer superior corrosion resistance, enhanced efficiency, and extended service life, making them an ideal choice for electrolysis applications in this industry.

The following anodes are commonly used in various electrochemical processes and applications due to their specific properties and performance characteristics. Here is a brief description of each type of anode:

1. Ruthenium-Iridium Titanium Anode: This type of anode is coated with a combination of ruthenium and iridium oxides. It offers excellent corrosion resistance, high current efficiency, and stability in harsh environments. It is commonly used in industries such as electrolytic water treatment, electrochlorination, and cathodic protection systems.

2. Ruthenium-Iridium-Stannum Titanium Anode: This anode is coated with a mix of ruthenium, iridium, and stannum (tin) oxides. The addition of stannum enhances the anode's performance in terms of low chlorine evolution potential and extended lifespan. It is often used in chlor-alkali electrolysis, wastewater treatment, and other electrochemical processes.

3. Iridium-Tantalum Titanium Anode: This anode is coated with a combination of iridium and tantalum oxides. It provides excellent corrosion resistance, high current density capabilities, and long-term stability in aggressive electrolytic environments. It finds applications in chemical synthesis, water disinfection, and electroplating processes.

4. Ruthenium-Titanium Anode: This type of anode is coated solely with ruthenium oxide. It offers good corrosion resistance and an excellent balance between high current efficiency and cost-effectiveness. It is commonly used in electrowinning, electrorefining, and other metal recovery processes.

5. Platinum Titanium Anode: This anode is coated with platinum oxide. It provides exceptional corrosion resistance and catalytic activity, making it suitable for various electrochemical applications, including electroplating, electrolysis, and fuel cell technology.

6. Lead Dioxide Titanium Anodes: These anodes are coated with lead dioxide (PbO2). They offer excellent corrosion resistance and are commonly used in processes that require high oxygen evolution capabilities, such as electrolytic cells used for chlorine production, water treatment, and electrowinning of non-ferrous metals.

Each type of MMO-coated anode has its specific advantages and applications, and the selection depends on factors such as the electrochemical process requirements, operating conditions, and desired performance parameters.

Latest News

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China