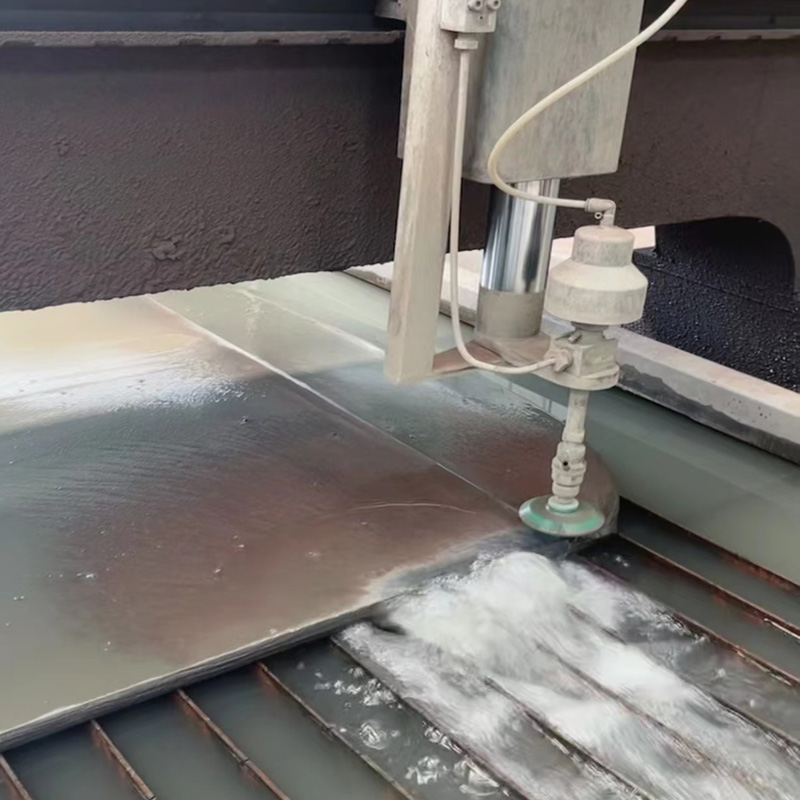

Waterjet cutting for titanium metal

Water jet cutting Titanium

Water jet cutting is a versatile and precise cutting method that uses a high-pressure stream of water mixed with an abrasive material to cut through various materials. One of the materials that can be effectively cut using water jet cutting is titanium. In this article, we will explore the benefits and applications of titanium water jet cutting.

Benefits of Titanium Water Jet Cutting

Precision

- Water jet cutting offers exceptional precision, allowing for intricate and complex designs to be cut accurately.

- This precision is particularly important when working with titanium, as it is a strong and durable material that requires precise cutting to maintain its integrity.

No Heat-Affected Zone (HAZ)

- Titanium is known to be sensitive to heat, which can cause it to lose its desirable properties.

- Water jet cutting does not generate heat during the cutting process, eliminating the risk of a heat-affected zone (HAZ) and preserving the material's properties.

Versatility

- Water jet cutting can be used to cut titanium of various thicknesses, making it suitable for a wide range of applications.

- It can cut through titanium sheets, plates, tubes, and other forms with ease.

Clean and Environmentally Friendly

- Water jet cutting is a clean and environmentally friendly cutting method.

- It does not produce hazardous fumes or dust, making it a safe option for both operators and the environment.

Our Titanium and titanium alloy plates, rods, tubes, fittings and forgings can be water jet cut upon requests.

Water jet cutting for titanium alloy description, advantages and applications:

Water jet cutting is a cutting technique which uses high-pressure streams of water mixed with abrasive particles to precisely cut titanium. This method has become highly sought after due to its precise cuts, providing numerous advantages over traditional methods.

1. Precision: With water jet cutting titanium, precision cuts can be performed precisely and with minimal tolerance, providing clean edges without warping, distortion or heat-affected zones.

2. Versatile: Water jet cutting can easily handle cutting titanium of different thicknesses - from thin sheets to thick blocks - with complex shapes, angles and patterns easily handled by this technology.

3. No heat-affected zone: Water jet cutting stands apart from other thermal cutting methods like laser or plasma cutting in that it doesn't produce heat, eliminating thermal distortion or alteration to material properties - something especially valuable when working with titanium, which is highly heat sensitive.

4. No Mechanical Stress: Water jet cutting exerts minimal force on material, decreasing any chance of mechanical strain or damage.

5. Environmentally friendly: Since cutting uses only water and abrasives, it is an eco-friendly process with no harmful emissions or byproducts that could harm our planet.

1. Aerospace industry: Water jet cutting titanium components is widely utilized for manufacturing aircraft components like turbine blades, engine casings and structural parts made of titanium.

2. Automotive industry: Waterjet technology can accurately cut titanium parts for automotive exhaust systems, motorbike frames and suspension components using waterjet cutting technology.

3. Medical Industry: Water jet cutting technology is utilized extensively in the production of titanium implants, surgical instruments and dental prosthetics where precision and minimal thermal effects are essential components.

4. Custom Fabrication: Water jet cutting allows for intricate titanium fabrication projects such as architectural signage, decorative items and jewelry design.

5. Defense Industry: Titanium parts used for military equipment like tanks, submarines and missiles can be cut with precision using water jet technology for precise use in cutting.

Overall, water jet cutting provides superior precision, versatility, and application to cutting titanium sheets in many industries - making it the preferred method.

Water jet cutting has quickly become the go-to method for cutting titanium alloys such as GR5, due to its ability to produce precise cuts with minimal heat-affected zones. Titanium alloys are known for their strength and corrosion resistance; however, they can be difficult to cut using traditional methods due to their hardness.

Water jet cutting works by employing a high-pressure jet of water mixed with abrasive particles to erode materials such as titanium alloy. The water jet is focused into a narrow stream and accelerated at high velocities for efficient titanium alloy cutting.

Process for water jet cutting is relatively straightforward and can be performed using computer-controlled machines. A CAD/CAM software program is used to define desired shapes or patterns, then followed by water jet cutter. Water jet cutting involves mixing water and abrasive materials like garnet or aluminum oxide into its mixture for greater cutting power and precision.

When cutting titanium alloy GR5 with a water jet, it is essential to take note of its unique properties. Titanium alloys tend to be harder than other metals, so an increased pressure and larger particle size might be required in order to achieve optimal cutting speeds and efficiency.

Proper safety precautions must be observed when working with water jet cutting machines, as the high-pressure water can be very hazardous if handled incorrectly. Operators should wear protective clothing and goggles and ensure that the cutting area is contained to avoid accidents from occurring.

Overall, water jet cutting is an efficient method for cutting titanium alloy GR5, as it produces clean cuts with minimal heat production or distortion. Water jet cutting has proven its worth in aerospace, automotive and medical settings for applications involving titanium alloys.

When water jet cutting titanium alloys such as GR5, there are key dimensions requirements to keep in mind in order to ensure accurate cuts that meet desired dimensions of the final product. Here are a few factors worth keeping in mind:

1. Thickness: Water jet cutting can effectively handle various titanium thicknesses; however, cutting speed and efficiency will depend on each thickness. Water jet cutting works particularly well with titanium alloys up to 6 inches thick while thicker materials may require multiple passes or adjustments in order to achieve optimal results.

2. Tolerance: The tolerance requirements vary based on application and industry. Water jet cutting services generally achieve tight tolerances within +/- 0.005 inches depending on machine configuration; it is wise to consult your water jet cutting provider in order to identify achievable tolerances for your project.

3. Kerf Width: When discussing water jet cutting, "kerf width" refers to the width of cut created by water jet cutting machines. In general, it typically ranges between 0.030-0.060 inches depending on material thickness and machine setup; thus it's essential to account for it when designing parts and components in order to meet desired dimensions.

4. Nesting and Material Utilization: When planning water jet cutting operations, it is recommended to optimize the layout of parts on the material sheet so as to minimise material waste while increasing utilization rates. Proper nesting techniques can help cut costs significantly while improving efficiency by increasing the number of parts cut from a single titanium sheet.

5. Part Complexity: Water jet cutting is highly versatile and capable of creating intricate shapes and designs, however the more intricate your parts may be the longer the cutting process may take - something to bear in mind when considering project timeline and cost estimates.

Dimension requirements may depend on the particular water jet cutting machine and capabilities of its service provider, so it is wise to consult a water jet cutting specialist about your particular requirements to make sure they can be fulfilled.

Latest News

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China