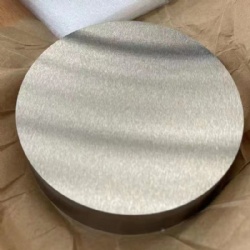

Products >> Tungsten >>

high purity tungsten balls

- Product No.:2023114105949

How Are Tungsten Balls Used in Industry?

Tungsten balls are small, spherical components made from tungsten or tungsten alloys. They are known for their exceptional strength and high density, making them ideal for a wide range of industrial applications.

From precision engineering to aerospace and medical fields, tungsten balls play a significant role in various industries. These versatile components provide durability, density, and strength that make them indispensable in many operations.

Key Takeaways:

- Tungsten balls are small, spherical components made from tungsten or tungsten alloys

- They are known for their exceptional strength and high density

- Tungsten balls find extensive use in precision engineering applications

- They are ideal for manufacturing tooling applications such as ball-point pens, valves, and mixing equipment

- The aerospace industry relies on tungsten balls for various purposes, including as components in gyroscopes and navigation systems.

What Are Tungsten Balls?

Tungsten balls are small, sphere-shaped components made from tungsten or tungsten alloys. They are known for their exceptional strength and high density, making them a popular choice in various industries for different purposes. Tungsten balls are made using a powder metallurgy process, where powdered tungsten or a tungsten alloy is formed into a ball shape and then sintered at high temperatures to create a dense, solid structure.

The size and material composition of tungsten balls can vary depending on their intended use. They can range in size from a few millimeters to several centimeters, and their composition can include tungsten carbide or other alloys for added durability.

Did You Know? Tungsten balls have the highest density of any metal, and their density is comparable to that of gold or platinum.

Precision Engineering Applications

Tungsten balls find extensive use in precision engineering applications due to their exceptional strength and uniform size.

Ball Bearings

Tungsten balls are ideal for ball bearings, providing superior performance due to their high density and precision manufacturing. They are used in applications such as flow meters, pendulums, and calibration weights where accuracy is critical.

Calibration Weights

Tungsten balls are also used as calibration weights in many industries. Due to their consistent size and weight, they are ideal for ensuring scales are accurate and consistent.

Flow Meters

Flow meters are devices used to measure the rate of flow of a liquid or gas. Tungsten balls are used in the construction of flow meters due to their high density and precision, making them ideal for accurately measuring fluid flow.

Overall, tungsten balls are a crucial component in precision engineering applications, providing unparalleled accuracy and consistency.

Manufacturing and Tooling

In manufacturing, tungsten balls are highly valued for their durability and resistance to wear and corrosion. They are employed in various tooling applications, such as ball-point pens, valves, and mixing equipment. Their exceptional strength and precision make them ideal for use in demanding environments.

The Benefits of Tungsten Balls in Manufacturing

Tungsten balls provide numerous benefits in manufacturing, including:

|

Benefit |

Explanation |

|

Durability |

Tungsten balls are highly resistant to wear and corrosion, making them excellent options for use in harsh manufacturing environments. |

|

Uniformity of Size |

Tungsten balls are manufactured to precise specifications, ensuring uniformity of size that is vital to the performance of many manufacturing tools and machines. |

|

Strength and Precision |

Tungsten balls have exceptional strength and precision, making them ideal for use in specialized manufacturing tools and machines. They are capable of withstanding high levels of stress and pressure without degrading or losing their shape. |

Overall, tungsten balls are an indispensable component in the manufacturing industry, providing durability, precision, and strength in a wide range of tooling applications.

Aerospace Engineering

The aerospace industry is one of the primary sectors that rely on tungsten balls for various applications. The unique properties of tungsten make it an ideal material for aerospace engineering, where components must withstand harsh conditions and extreme temperatures.

Tungsten alloy balls find widespread use in counterweights for aircraft control systems, where precise weight distribution is essential for optimal performance. These balls are also used as ballast weights in satellites, ensuring the spacecraft's stability and controlled movements.

Tungsten balls are also utilized in gyroscopes and navigation systems in aerospace engineering. These components ensure accurate positioning, velocity, and orientation of the aircraft or spacecraft.

Tungsten in Spacecraft Shielding

Tungsten has high density and shielding capabilities, making it an excellent material for radiation shielding in spacecraft. Tungsten balls are used in spacecraft shielding to protect against cosmic rays and other forms of radiation that can be harmful to astronauts and equipment. Tungsten balls are also utilized in medical and nuclear applications for the same reason.

The use of tungsten balls in aerospace engineering demonstrates the versatility and durability of these components, making them indispensable for many critical space missions and operations.

Medical and Nuclear Applications

The applications of tungsten balls are not limited to engineering and manufacturing. They have become vital components in the medical and nuclear fields due to their high density and incredible strength.

One such application is radiation shielding, where tungsten balls provide a barrier that absorbs and redirects nuclear radiation away from patients and technicians, protecting them from exposure. Additionally, tungsten balls find use in radiotherapy devices, where their high density is useful for targeting specific cancer tissues and minimizing collateral damage to healthy cells.

"Tungsten alloy balls are an excellent choice for radiotherapy due to their ability to concentrate radiation on cancerous cells while minimizing damage to surrounding healthy tissues."

Furthermore, tungsten balls serve as essential components in diagnostic equipment, such as CT scanners and x-ray machines, providing clear and accurate imaging for medical professionals.

Sports and Recreation

Tungsten balls find their way into several sports and recreational activities, serving multiple purposes.

Billiards

In billiards, tungsten balls are used as cue ball replacements or for playing snooker. Tungsten's high density compared to other materials makes it an excellent choice for billiard balls. When struck, tungsten balls have a unique sound that sets them apart from other balls. They offer a level of control that other materials can't match, making them perfect for professional level play.

Golf

Tungsten balls are also used in golf as weights for clubs. Tungsten's density allows for a smaller head on the club, distributing the mass towards the bottom of the club for greater control and accuracy. These balls also improve a golfer's ball striking and consistency, thanks to their perfect balance and weight.

Table Tennis

Tungsten balls are used in table tennis as well. These balls are designed to withstand hard hits and impacts, ensuring greater durability and longevity. For players, these balls provide a consistent performance level throughout extended playtime.

Conclusion

Tungsten balls are an integral part of various industries due to their exceptional strength, density, and durability. From precision engineering to manufacturing, aerospace, medical, and even sports, tungsten balls find extensive use in different applications.

Whether it is for ball bearings, flow meters, valves, or counterweights in aircraft control systems, tungsten balls provide the necessary properties that make them ideal for these purposes. Their high density also makes them an excellent choice for radiation shielding in the medical and nuclear fields.

Furthermore, numerous tungsten ball manufacturers and suppliers specialize in providing high-quality products that adhere to industry standards. Their role in ensuring availability and quality cannot be overstated.

In conclusion, tungsten balls are indispensable components that play a crucial role in various industries. Their unique properties make them a preferred choice for many applications, and their versatility ensures that their demand will continue to rise in the future.

FAQ

How are tungsten balls used in industry?

Tungsten balls are used in various industries for applications such as precision engineering, manufacturing, aerospace, medical, nuclear, and sports. They provide strength, density, and durability in different operations.

What are tungsten balls?

Tungsten balls are small, spherical components made from tungsten or tungsten alloys. They are known for their high density and exceptional strength, making them versatile for use in different industries.

What are the precision engineering applications of tungsten balls?

Tungsten balls are widely used in precision engineering applications such as ball bearings, flow meters, pendulums, and calibration weights. Their uniform size and high density make them ideal for these purposes.

How are tungsten balls used in manufacturing and tooling?

In manufacturing, tungsten balls are used in tooling applications like ball-point pens, valves, and mixing equipment. Their durability and resistance to wear and corrosion make them a preferred choice in demanding environments.

How are tungsten balls used in aerospace engineering?

Tungsten balls are utilized in the aerospace industry for various purposes. They serve as counterweights in aircraft control systems, ballast weights in satellites, and components in gyroscopes and navigation systems.

What are the medical and nuclear applications of tungsten balls?

Tungsten balls have vital applications in the medical and nuclear fields. They are used as radiation shielding, in radiotherapy devices, and as components in diagnostic equipment due to their high density.

How are tungsten balls used in sports and recreation?

Tungsten balls are employed in sports and recreational activities. They are used in billiards as cue ball replacements, in golf as weights for clubs, and even in table tennis balls for improved durability.

Where can I find tungsten ball manufacturers and suppliers?

Numerous manufacturers and suppliers specialize in providing high-quality tungsten balls. These professionals play a crucial role in ensuring availability and adherence to industry standards.

What is the significance of tungsten balls across industries?

Tungsten balls play a significant role in various industries, providing strength, density, and durability in precision engineering, manufacturing, aerospace, medical, nuclear, and sports applications. They are versatile components that are indispensable for many operations.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China