Products >> Titanium >> Titanium tube

High strength titanium tubes

- Product No.:TG-861

- Material Grade:commercially pure titanium or titanium alloy

- Size:3/4 inch to 36 inches

Titanium alloys have become increasingly popular due to their outstanding properties and widespread applications. This essay will investigate their use as heat exchanger tubes conforming to ASTM B861 or B338 standards; with particular attention being paid to their strength.

Titanium is an impressively strong material.

Titanium stands out among metals due to its remarkable strength-to-weight ratio. This extraordinary strength stems from numerous factors. Titanium's hexagonal close-packed crystal allows efficient packing of its atoms, leading to stronger interatomic bonds.

Pure titanium's strength ranges between 140 MPa (20psi), 550MPa (80,000psi) and 240MPa (35,000psi), both at ultimate tensile. When alloyed, titanium gains in strength further; Ti-6Al-4V alloy is one such popular alloy which boasts yield values up to approximately 950MPa (138ksi) with ultimate tensile capacities exceeding 1100MPa (160,000psi).

Titanium alloys for enhanced performance:

Titanium alloys have revolutionized industries that demand strong and corrosion-resistant materials. Titanium alloys outperform pure titanium in strength and performance terms; furthermore, their chemical and corrosion resistance makes them especially suitable for use in hazardous environments.

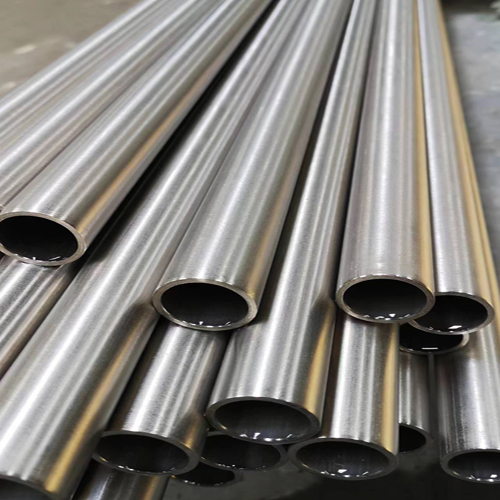

Heat exchangers typically consist of titanium alloy tubes which conform to ASTM B861 or B338 standards, making them highly durable and strong enough to withstand the rigorous conditions encountered when exchanging heat. Furthermore, these tubes offer resistance against corrosion, erosion, and fouling for use in various industrial processes.

Titanium Alloy Tubes and Their Properties: An Overview:

Heat exchangers make an excellent use for titanium and titanium alloy tubes due to their properties. First, titanium has superior thermal conductivity for efficient heat transfers within the exchanger; moreover, its lightweight nature and low density allows heat exchangers to stay lightweight yet structurally sound.

Titanium and its alloys boast impressive corrosion resistance that is essential to heat exchanger performance, offering protection from aggressive liquids, high temperatures, and aggressive chemicals - as well as long-term reliability with reduced maintenance costs and enhanced operational efficiency. This makes these alloys essential components in heat exchanger design.

Conclusion: Heat exchangers can benefit greatly from using titanium and titanium alloy tubes that meet ASTM B861 or B338 specifications, as these provide superior strength, corrosion resistance, properties, weight reduction, and performance across a wide variety of industries.

Titanium and titanium alloy tubes have revolutionized heat transfer thanks to their excellent thermal conductivity and low weight. Furthermore, these resilient materials also resist corrosion - two traits which will become even more advantageous as technology continues to advance. Titanium alloys will soon be utilized more widely within heat exchangers.

Titanium and its alloys offer industries seeking more powerful, lighter and more resilient heat exchanger materials an invaluable asset.

ASTM B861 Grade 2 Titanium Alloy Seamless Pipes Appllication

Titanium Alloy Pipe is used in various applications:

Chlorination systems utilise flue gas scrubbers and sulfur dioxide scrubbers, as well as outlet ducting and stack liners, for use in power plants, pulp and paper bleach plants, sulfur dioxide scrubbers, weld overlay of less corrosion resistant metals and acid production and pickling systems.

Pharmaceutical industries utilize alloy fittings and tubing to prevent contamination from corrosion-related failures in cellophane manufacturing, chlorination systems and pesticide production.

Incineration scrubber systems for chemical processing industries utilise equipment like flue gas scrubbers, chlorination systems and sulfur dioxide scrubbers, pulp and paper bleach plants with pickling systems, nuclear fuel reprocessing as well as waste water processing equipment.

Pollution control components including stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings; as well as flue gas desulfurization systems (FDS) may include heat exchangers, reaction vessels, evaporators, transfer piping and transfer valves are often necessary in processing components of such systems; so too may sour gas wells be necessary in Pulp and Paper production as well as Waste treatment processes.

Pharmaceutical and food processing equipment

Previous Product:titanium tubes price per kg

Next Product:external threaded titanium tube

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China