Products >> Titanium >> Titanium pipe fittings

ASTM B363 titanium fittings

- Product No.:202382517118

- Price:10$-1200$

- Material Grade:Titanium Gr2

- Size:1/2 inch to 48 inches

Premium ASTM B363 Titanium Fittings for Sale

When it comes to high-quality and corrosion-resistant ASTM B363 titanium fittings, there is no better choice than those available for sale here. Our fittings are designed to meet the highest standards of quality and performance, delivering exceptional durability and long-lasting results for various piping solutions.

Key Takeaways

- Our ASTM B363 titanium fittings are made to the highest standards of quality and performance.

- They are corrosion-resistant and ideal for use in a wide range of industrial piping systems.

- Our fittings provide exceptional durability and longevity, even in harsh environments.

- When choosing titanium fittings, it's essential to consider factors such as quality, performance, and adherence to standards.

- You can purchase high-quality ASTM B363 titanium fittings from reputable suppliers.

Understanding ASTM B363 Titanium Fittings

ASTM B363 titanium fittings come in different forms, including pipe and tube fittings. These fittings are made of high-quality titanium material and are highly corrosion resistant, which makes them ideal for use in various applications. Titanium pipe fittings are used to connect different lengths of pipes, while titanium tube fittings are used to connect tubes for fluid transportation across various industries.

The corrosion-resistant properties of ASTM B363 titanium fittings make them suitable for use in corrosive environments, such as those found in the chemical, oil and gas, and marine industries. This type of fitting is also suitable for use in water treatment plants and desalination facilities where resistance to saltwater corrosion is critical. It is a reliable and durable material that can withstand harsh environmental conditions.

When sourcing ASTM B363 titanium fittings, it is essential to conect those that adhere to the industry standards to ensure performance, quality, and safety. These corrosion-resistant fittings offer a wide range of possibilities suitable for use across various industries, providing practical and reliable solutions for most piping needs.

Advantages of Titanium Fittings

If you seek durable and reliable fittings for industrial applications, titanium fittings could be your best option. Titanium offers several benefits that make it stand out from other materials, including:

- Durability: Titanium fittings have a high strength-to-weight ratio, which makes them highly resistant to wear and corrosion. They can withstand extreme temperatures and pressures and maintain their performance over a long lifespan.

- Reliability: Titanium fittings offer consistent performance and stability in challenging environments, ensuring uninterrupted operations in various industrial settings.

Additionally, titanium is a non-toxic material that is safe for human consumption and does not contaminate the fluids it comes into contact with. These features make titanium fittings suitable for diverse sectors, including chemical, petrochemical, and pharmaceutical industries.

Common Uses of ASTM B363 Titanium Fittings

ASTM B363 titanium fittings are highly versatile and can be used in various applications. Two common uses of these premium fittings are in socket weld and threaded connections. Socket weld fittings are designed to connect pipes by welding them together at the joint, while threaded fittings use a threaded connection to join pipes. Titanium socket weld fittings are commonly used in high-pressure systems that require strong and leak-free connections. Meanwhile, titanium threaded fittings are ideal for applications that require frequent disassembly, such as maintenance and repairs.

Overall, titanium fittings provide superior performance and durability in comparison to other metals. They are an outstanding choice for different piping systems, including petrochemical, oil and gas, and offshore industries.

Factors to Consider When Choosing Titanium Fittings

Choosing the right titanium fittings is crucial for ensuring the quality and performance of your piping systems. When purchasing fittings, there are several factors to consider to ensure that they meet your needs and requirements.

One key factor to keep in mind is to buy top-rated titanium fittings. These fittings have been tested and approved for their quality and performance, giving you peace of mind when installing them in your industrial environment. Top-rated fittings also provide long-term reliability and reduce the risk of failure or malfunction.

Other factors to consider when choosing titanium fittings include:

- the specific application or use case of the fitting

- the material and properties of the fitting to ensure compatibility with your system and environment

- the size and shape of the fitting to ensure a good fit and connection with other components

- the pressure rating of the fitting to ensure it can handle the required pressure in your system

- the certification and compliance of the fitting with industry standards and regulations

Considering these factors when ordering titanium fittings can help you make the right choice for your piping system, ensuring long-term efficiency and reliability.

Installation and Maintenance of Titanium Fittings

Titanium fittings are known for their durability and long-lasting performance. However, proper installation and maintenance are crucial to ensuring that they remain durable throughout their lifespan. By following the guidelines below, you can guarantee the maximum durability of your titanium fittings.

Installation Guidelines

- Ensure that the fittings are clean and free of debris before installation.

- Use the manufacturer's recommended torque settings to avoid over-tightening or under-tightening the fittings.

- Apply appropriate sealants to all threaded connections to prevent leaks.

- Check for proper alignment between the piping and fittings before tightening.

Maintenance Tips

- Conduct regular inspections to ensure that there is no corrosion or damage.

- Keep the fittings clean and free of dirt and debris.

- Replace any damaged fittings immediately to prevent further damage or leaks.

- Use non-abrasive cleaners and tools during maintenance to avoid damaging the fittings.

By following these simple guidelines, you can ensure that your durable titanium fittings remain in top shape and perform at their best.

Exploring the ASTM B363 Standard

The ASTM B363 standard is a crucial aspect of ensuring the quality and performance of your titanium fittings. This standard provides strict guidelines for the manufacturing and testing of ASTM B363 titanium fittings, ensuring they meet the highest standards of quality and performance.

When choosing fittings for your piping system, it is essential to consider those that adhere to the ASTM B363 standard. This ensures that your fittings provide exceptional corrosion resistance, durability, and longevity.

Furthermore, adherence to this standard ensures that your fittings withstand harsh environments and high-pressure applications, meeting the specific needs of your piping system.

It is crucial to work with a supplier that offers fittings that adhere to the ASTM B363 standard. By doing so, you can be confident that you are using only the highest quality and most reliable fittings in your industrial and commercial applications.

Where to Buy High-Quality ASTM B363 Titanium Fittings

If you're looking to purchase high-quality ASTM B363 titanium fittings, it's crucial to find a reputable supplier with a track record of delivering top-notch products. Here are some tips on where to look:

- Check online marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide range of titanium fittings from different suppliers. Make sure to read reviews and ratings from previous buyers to determine the quality and reliability of the supplier.

- Contact manufacturers: Reach out to certified manufacturers of ASTM B363 titanium fittings and ask for their list of authorized distributors. This will help ensure that you get genuine, high-quality fittings that meet industry standards.

- Consult with industry experts: Speak to industry experts like engineers, contractors, and procurement specialists, and ask for their recommendations on where to buy high-quality titanium fittings. Their insights can help you make informed decisions and avoid potential pitfalls.

When choosing a supplier, it's essential to consider factors like price, lead times, and shipping options. Make sure that you get quotes from multiple suppliers and compare them before making a final decision. With the right supplier, you can ensure that your piping system performs at its best with high-quality and reliable titanium fittings.

Benefits of Using Corrosion-Resistant Titanium Fittings

When it comes to piping systems, one of the crucial factors to consider is corrosion resistance. Corrosion can cause significant damage and reduce the lifespan of your piping infrastructure. That is where corrosion-resistant titanium fittings come into play.

Using titanium fittings with anti-corrosive properties can offer numerous benefits:

- Long-lasting durability in harsh environments

- Resistance to corrosion and oxidation

- Reduced maintenance costs and downtime

- Compatibility with various piping materials

- Lightweight construction for easy handling and installation

These advantages make corrosion-resistant titanium fittings a top choice for industries dealing with corrosive materials and environments, such as the oil and gas, chemical, and marine industries.

Investing in high-quality corrosion-resistant titanium fittings ensures that your piping system operates efficiently for a significant period, minimizing the need for repairs and downtime costs.

Conclusion

Choosing the right fittings for your piping system is crucial to ensure optimal performance and longevity. ASTM B363 titanium fittings offer premium quality, durability, and corrosion resistance, making them a top choice for various industrial applications.

By choosing titanium fittings that adhere to the ASTM B363 standard, you can rest assured that you are getting high-quality products that will meet your needs. Additionally, proper installation and maintenance are essential to ensure the longevity of these fittings and their ability to withstand harsh conditions.

Investing in corrosion-resistant titanium fittings can deliver significant benefits, including increased efficiency and cost savings in the long term. When opting a supplier, ensure that you contact one that offers top-rated titanium fittings and has a proven track record of providing reliable and high-quality products.

In summary, ASTM B363 titanium fittings are a reliable and durable solution for various industrial piping systems. By following the guidelines and insights provided in this article, you can make an informed decision when choosing the right fittings for your specific application.

FAQ

What are ASTM B363 titanium fittings?

ASTM B363 titanium fittings are high-quality fittings made from titanium, a corrosion-resistant material. These fittings are designed to provide durable and reliable connections in various piping systems.

What types of titanium fittings are available?

ASTM B363 titanium fittings are available in various types, including pipe fittings and tube fittings. These fittings are designed to meet specific requirements and provide corrosion resistance in different applications.

What are the advantages of using titanium fittings?

Titanium fittings offer several advantages, including their durability and reliability. They are resistant to corrosion, making them suitable for use in demanding environments. Titanium fittings also have high strength-to-weight ratio, low density, and excellent heat resistance.

In what applications are titanium fittings commonly used?

ASTM B363 titanium fittings are commonly used in applications that require socket weld or threaded connections. They are widely employed in industries such as aerospace, marine, chemical processing, power generation, and oil and gas.

What factors should be considered when choosing titanium fittings?

When ordering titanium fittings, it is crucial to consider their quality and performance. Opting for top-rated fittings ensures reliability and durability. Other factors to consider include compatibility with the piping system, type of connection required, and specific application requirements.

How should titanium fittings be installed and maintained?

Proper installation and maintenance are essential for maximizing the longevity of titanium fittings. It is crucial to follow manufacturer guidelines and use appropriate tools and techniques. Regular inspection and cleaning, as well as timely repairs, are necessary for ensuring the continued performance of titanium fittings.

What is the significance of the ASTM B363 standard?

The ASTM B363 standard establishes the specifications and requirements for titanium fittings, ensuring their quality and performance. Choosing fittings that comply with this standard provides assurance of high-quality and reliable products.

Where can I buy high-quality ASTM B363 titanium fittings?

There are reputable suppliers and distributors that offer high-quality ASTM B363 titanium fittings. It is recommended to conduct thorough research, consider suppliers with a proven track record, and seek recommendations from industry professionals to ensure the purchase of reliable and durable fittings.

What are the benefits of using corrosion-resistant titanium fittings?

Corrosion-resistant titanium fittings offer several benefits. They can withstand corrosive environments, reducing the risk of leaks and failures. These fittings provide long-term efficiency and reliability in piping systems, ultimately saving maintenance costs and enhancing overall performance.

Titanium Gr2 fittings include:

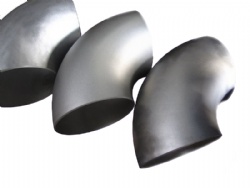

45° titanium elbows

90° titanium elbows

180° titanium returns

Titanium equal tees (titanium straight tees)

Titanium reducing tees

Titanium concentric reducers

Titanium eccentric reducers

Titanium lap joint stub ends

Titanium reducers

Titanium couplings

Titanium bushings

Titanium caps

Titanium pipe nipples

Titanium pipe plugs

R50400 titanium pipe fittings with purity 99.8%

The pipe fittings size from nominal pipe size (NPS) 1/2"-48" or Diameter Nominal (DN) 15-1200

Wall thickness: Schedule 10S to Schedule STD. the maximum thickness is 20mm

R50400 Titanium Pipe Fittings are made by titanium tubes or titanium sheets.

The raw material is 100% PMI. the welding seams are 100% RT according to UW-51 requirements.

Material certificate EN 10204-3.1 affiliated.

R50400 Titanium Pipe Fittings are fabricated with ASTM B363, ASME B16.9

R50400 material grade is equivalent to Titanium WPT2

Hengze Industry Co., Ltd. is a leading producer and exporter of high-quality titanium pipe fittings grade 2. With years of experience and expertise in the industry, we have established ourselves as a trusted supplier in both domestic and international markets. Our titanium pipe fittings grade 2 are manufactured using top-grade materials and advanced technology, ensuring excellent durability, corrosion resistance, and high functionality. We take pride in our commitment to delivering products that meet international quality standards, and our skilled team of professionals works tirelessly to ensure customer satisfaction. Whether you require titanium pipe fittings for industrial, aerospace, or medical applications, Hengze Industry Co., Ltd. is your go-to supplier for reliable and efficient solutions.

Titanium Pipe Fittings Grade 2 Ranges:

1. Titanium Pipe Elbows: Our grade 2 titanium pipe elbows are designed to provide smooth directional changes in piping systems. They are available in various angles and sizes to suit different applications.

2. Titanium Pipe Tees: Our titanium pipe tees are used to create branching connections in piping systems. They offer excellent strength and corrosion resistance, making them ideal for demanding environments.

3. Titanium Pipe Reducers: Our grade 2 titanium pipe reducers are used to connect pipes with different diameters, ensuring efficient flow and compatibility. They are available in both concentric and eccentric designs.

4. Titanium Pipe Caps: Our titanium pipe caps are used to seal the ends of pipes, providing protection against dirt, debris, and moisture. They are available in various sizes and can be easily installed or removed.

5. Titanium Pipe Flanges: Our grade 2 titanium pipe flanges are used for the connection of pipes, valves, and other components. They are designed to withstand high pressure and temperature conditions, ensuring reliable and leak-free performance.

6. Titanium Pipe Nipples: Our titanium pipe nipples are used for extending or connecting pipes in various applications. They are available in different lengths and diameters to suit specific requirements.

7. Titanium stub ends grade 2 are another important component in piping systems. They are used to create a secure and leak-proof connection between pipes and other fittings. Here are some key features and benefits of titanium stub ends grade 2:

7.1 Corrosion resistance: Grade 2 titanium is known for its excellent corrosion resistance, making it suitable for various harsh environments, including chemical processing, marine applications, and offshore installations.

7.2 Lightweight: Titanium is a lightweight metal, which makes it easier to handle and install. This characteristic is particularly advantageous in industries where weight reduction is a priority.

7.3 High strength: Despite its lightweight nature, grade 2 titanium exhibits impressive strength properties. This ensures the durability and longevity of the stub ends, even in demanding conditions.

7.4 Temperature resistance: Titanium grade 2 can withstand high temperatures, making it suitable for applications where elevated temperatures are involved.

7.5 Compatibility: Titanium stub ends grade 2 are compatible with a wide range of piping materials, including titanium, stainless steel, and other alloys. This versatility allows for seamless integration into various piping systems.

7.6 Low maintenance: Titanium is known for its low maintenance requirements. It is resistant to scaling, fouling, and corrosion, reducing the need for frequent cleaning or maintenance.

At Hengze Industry Co., Ltd., we strive to provide a comprehensive range of titanium pipe fittings grade 2 to meet the diverse needs of our customers. Our products are manufactured with precision and undergo strict quality control measures to ensure exceptional performance and reliability. Contact us today to learn more about our titanium pipe fittings grade 2 and how they can enhance your piping systems.

Titanium pipe fittings are commonly used in water treatment applications due to their excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility. They are particularly well-suited for use in harsh environments, such as those involving seawater, wastewater, or aggressive chemicals.

Titanium pipe fittings are available in a wide variety of types and sizes, including:

- Elbows

- Tees

- Crosses

- Reducers

- Couplings

- Flanges

- Stub ends

They can be connected to other pipes and fittings using a variety of methods, including welding, threading, and mechanical flanging.

Some of the specific benefits of using titanium pipe fittings in water treatment applications include:

- Superior corrosion resistance: Titanium is highly resistant to corrosion from a wide range of chemicals, including chlorine, ozone, and salt water. This makes it ideal for use in water treatment plants, where pipes and fittings are constantly exposed to aggressive chemicals.

- High strength-to-weight ratio: Titanium is a very strong material, but it is also relatively lightweight. This makes it ideal for use in applications where weight is a concern, such as in overhead piping systems.

- Biocompatibility: Titanium is biocompatible, meaning that it is non-toxic and does not react with the human body. This makes it ideal for use in water treatment applications where the water will be used for drinking or irrigation.

Overall, titanium pipe fittings are an excellent choice for water treatment applications due to their superior corrosion resistance, high strength-to-weight ratio, and biocompatibility.

Here are some examples of how titanium pipe fittings are used in water treatment applications:

- Seawater desalination: Titanium pipe fittings are used in seawater desalination plants to transport and process seawater. Titanium is resistant to the corrosive effects of seawater, making it ideal for this application.

- Wastewater treatment: Titanium pipe fittings are also used in wastewater treatment plants to transport and process wastewater. Titanium is resistant to the corrosive effects of wastewater, as well as to the biofouling that can occur in wastewater systems.

- Drinking water treatment: Titanium pipe fittings are used in drinking water treatment plants to transport and process drinking water. Titanium is biocompatible and does not react with the water, making it ideal for this application.

Here are some specific examples of how titanium pipe fittings are used in water treatment:

- Disinfection systems: Titanium fittings are used in disinfection systems to safely deliver and mix chemicals such as chlorine and ozone.

- Filtration systems: Titanium fittings are used in filtration systems to connect and redirect pipes and tubes, and to prevent corrosion of the filtration media.

- Ion exchange systems: Titanium fittings are used in ion exchange systems to connect and redirect pipes and tubes, and to prevent corrosion of the ion exchange resin.

- Chemical dosing systems: Titanium fittings are used in chemical dosing systems to safely deliver and mix chemicals such as acids and bases.

- Wastewater treatment systems: Titanium fittings are used in wastewater treatment systems to connect and redirect pipes and tubes, and to withstand the harsh operating conditions found in these systems.

Overall, titanium pipe fittings offer a number of benefits for water treatment applications, including:

- Improved water quality: Titanium's corrosion resistance and non-toxicity help to ensure that treated water meets all quality standards.

- Reduced maintenance costs: Titanium's long service life and low maintenance requirements help to save money on water treatment system operation and upkeep.

- Increased system reliability: Titanium's strength and durability help to reduce the risk of system failures.

In addition to the above applications, titanium pipe fittings are also used in a variety of other water treatment applications, such as:

- Cooling water systems

- Fire protection systems

- Industrial water treatment systems

- Power plant water treatment systems

Titanium Pipe Fittings Grade 2 Specifications:

|

Titanium Pipe Fittings Grade 2 Specifications |

|

|

Titanium Elbows |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Tees |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Reducers |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Stub Ends |

1/2" to 24" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

Titanium Caps |

1/2" to 48" Schedule 5S, Schedule 10S, Schedule 40S, Schedule 80S Etc |

|

|

|

|

Titanium Elbows |

ASTM B363, ANSI B16.9, ASME B16.9 |

|

Titanium Tees |

ASTM B363, ANSI B16.9, ASME B16.9 |

|

Titanium Reducers |

ASTM B363, ANSI B16.9, ASME B16.9 |

|

Titanium Stub Ends |

ASTM B363, ANSI B16.9, ASME B16.9, MSS SP-43 |

|

Titanium Caps |

ASTM B363, ANSI B16.9, ASME B16.9 |

Titanium Pipe Fittings Grade 2 Material Properties and Chemical Composition

|

Chemical Composition ( WT %) |

||||||||

|

Requirement |

Ti |

C |

O |

N |

H |

Fe |

Residual Element |

|

|

Remainder |

≤ |

≤ |

≤ |

≤ |

≤ |

Each |

Total |

|

|

Required |

0.08 |

0.25 |

0.03 |

0.015 |

0.3 |

0.1 |

0.4 |

|

|

Actual |

Balanced |

0.012 |

0.055 |

0.008 |

0.0014 |

0.031 |

0.1 |

0.4 |

|

Tensile Test |

||||||||

|

Requirement MIN |

Heat No. |

Tensile Strength |

Yield Strength 0.2% |

Elongation |

||||

|

[MPa] |

[MPa] |

[%] |

||||||

|

345 MIN. |

275-450. |

20 MIN. |

||||||

|

Actual |

TX-01 |

385 |

320 |

34 |

||||

|

Actual |

PX-01 |

385 |

320 |

34 |

||||

Titanium Pipe Fittings Grade 2 Types:

|

Butt-welded Titanium Pipe Fittings Grade 2 |

Titanium Elbows with 90 Degree bending |

|

Titanium Elbows with 45 Degree bending |

|

|

Titanium Returns with 180 Degrees |

|

|

Titanium Elbows with Segmental |

|

|

Titanium Elbows with Long Radius |

|

|

Titanium Elbows with Short Radius |

|

|

|

|

|

Titanium Straight Tees |

|

|

Titanium Reducing Tees |

|

|

|

|

|

Titanium Concentric Reducers |

|

|

Titanium Eccentric Reducer |

|

|

|

|

|

Titanium Stub Ends with Long Pattern |

|

|

Titanium Stub Ends with Short Pattern |

|

|

|

|

|

Titanium Caps |

Frequently asked questions for titanium pipe fittings grade 2:

-

1. What is grade 2 titanium?

Grade 2 titanium is a commercially pure titanium alloy that offers excellent corrosion resistance, high strength, and good weldability. It is commonly used in various industries, including chemical processing, oil and gas, aerospace, and marine applications. -

2. What are the advantages of using grade 2 titanium pipe fittings?

Grade 2 titanium pipe fittings offer several advantages, including exceptional corrosion resistance, lightweight nature, high strength-to-weight ratio, excellent heat transfer properties, and biocompatibility. These fittings are also resistant to erosion and fatigue, making them ideal for demanding environments. -

3. What types of pipe fittings are available in grade 2 titanium?

Grade 2 titanium pipe fittings are available in various types, including elbows, tees, reducers, couplings, flanges, and caps. These fittings are designed to connect, control, or change the direction of the flow in titanium piping systems. -

4. Can grade 2 titanium pipe fittings be used in high-temperature applications?

Grade 2 titanium has a melting point of around 1,650°C (3,000°F), which makes it suitable for high-temperature applications. However, it is important to consider the specific temperature and environmental conditions to ensure the fittings will perform optimally. -

5. Are grade 2 titanium pipe fittings compatible with other materials?

Grade 2 titanium pipe fittings are compatible with a wide range of materials, including stainless steel, carbon steel, and other titanium alloys. However, it is essential to consider factors such as galvanic corrosion and differing thermal expansion coefficients when connecting different materials. -

6. How do I properly install and maintain grade 2 titanium pipe fittings?

Proper installation and maintenance are crucial for the longevity and performance of titanium pipe fittings. It is recommended to follow the manufacturer's guidelines and consult with professionals for installation. Regular inspections, cleaning, and preventive maintenance can help ensure the fittings function optimally. -

7. Where can I source grade 2 titanium pipe fittings?

Grade 2 titanium pipe fittings can be sourced from specialized suppliers, metal distributors, or manufacturers that deal with titanium products. It is important to choose a reliable supplier with a proven track record in providing high-quality titanium fittings.

Contact Us

Name: Mr. Ren

Tel: +86-18292471213

E-mail: info(at)intemetal.com

Add: Middle Section Baotai Road, Weibin District, 721013, Baoji, Shaanxi Province, China